Top 5 Reasons Why Wire Steel is Essential in Construction and Manufacturing

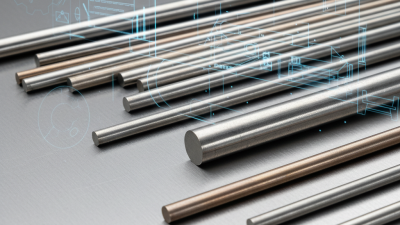

In the realm of construction and manufacturing, wire steel has emerged as an indispensable material, shaping the frameworks of modern infrastructure and production techniques. According to industry expert Dr. Emily Harper, a leading authority in materials science, "The versatility and strength of wire steel make it a cornerstone in both construction and manufacturing applications." With its unique properties, wire steel not only enhances structural integrity but also supports innovative design solutions.

As we delve into the top five reasons why wire steel is essential, we will explore its unmatched durability, cost-effectiveness, and adaptability in various projects. Its ability to withstand extreme conditions while maintaining performance efficiency has solidified wire steel's reputation as a vital resource in building resilient structures. Additionally, the ongoing advancements in wire steel technology continue to elevate its importance, making it a critical component in the pursuit of sustainable and efficient manufacturing processes. The following sections will illuminate how this remarkable material is shaping the future of construction and manufacturing.

Importance of Wire Steel in Structural Integrity and Durability

Wire steel plays a crucial role in ensuring structural integrity and durability in construction and manufacturing. According to a report by the American Iron and Steel Institute, over 70 million tons of steel are used each year in construction alone, with wire steel being a key component due to its high tensile strength and versatility. The material's ability to withstand tension makes it ideal for reinforcing concrete structures, ultimately enhancing their load-bearing capacity and longevity.

Moreover, the use of wire steel contributes significantly to the overall durability of structures. A study published by the International Journal of Structural Engineering indicates that structures reinforced with high-quality wire steel show improved resistance against environmental factors and mechanical stress. As a result, buildings and infrastructure utilizing wire steel can achieve a longer lifespan, reducing maintenance costs and ensuring safety for occupants. The properties of wire steel, such as its corrosion resistance and fatigue strength, make it an essential choice in modern construction practices aimed at building resilient frameworks.

Versatility of Wire Steel in Various Construction Applications

Wire steel is a fundamental component in the construction and manufacturing industries due to its incredible versatility. In construction, wire steel is utilized in various applications, including reinforcement for concrete structures. The thin strands of wire can be welded or tied together to create meshes or cages that provide the necessary tensile strength to combat the forces acting on buildings, bridges, and other infrastructures. This application is crucial, especially in areas prone to seismic activity, where reinforced concrete can significantly enhance a structure's resilience.

Apart from its role in reinforcement, wire steel finds extensive use in creating formwork and scaffolding systems. These systems are essential during the construction phase, offering support and stability for workers and materials. The lightweight nature of wire steel makes it easy to handle while ensuring reliability and robustness in scaffolding setups. Additionally, wire steel is employed in various manufacturing processes, including the production of wire ropes and cables used in cranes and lifting equipment. Its adaptability across a wide range of applications makes wire steel an indispensable material that supports the efficiency and safety of construction and manufacturing projects.

Cost-Effectiveness of Wire Steel in Manufacturing Processes

Wire steel stands out as a cost-effective solution in manufacturing processes, offering numerous advantages that contribute to overall savings. Its lightweight yet strong properties allow manufacturers to reduce material quantities without compromising structural integrity. This reduction in material usage translates to lower raw material costs, which is especially significant in industries where budget constraints are paramount. Furthermore, the ease of handling wire steel enhances operational efficiency, as workers can manipulate and transport these materials with minimal effort, thereby reducing labor costs.

Additionally, wire steel's versatility adds to its cost-effectiveness. It can be easily welded, bent, or shaped into various forms, making it suitable for a wide range of applications, from construction reinforcement to intricate manufacturing components. This adaptability allows manufacturers to streamline production processes and minimize downtime, ultimately leading to reduced operational expenses. Moreover, wire steel's durability and resistance to corrosion extend the lifespan of products, resulting in fewer replacements and maintenance costs over time. Such benefits make wire steel a valuable asset in both the construction and manufacturing sectors.

Top 5 Reasons Why Wire Steel is Essential in Construction and Manufacturing - Cost-Effectiveness of Wire Steel in Manufacturing Processes

| Reason | Benefit | Cost Savings (%) | Durability (Years) |

|---|---|---|---|

| High Tensile Strength | Enhances structural integrity. | 20% | 50 |

| Versatility | Applicable in various projects. | 30% | 40 |

| Reduced Material Waste | Optimizes resource efficiency. | 15% | 30 |

| Lightweight | Easier handling and transport. | 25% | 35 |

| Cost-Effective Production | Lower manufacturing costs. | 40% | Lifetime |

Wire Steel's Role in Enhancing Safety Standards in Construction

Wire steel plays a pivotal role in enhancing safety standards in construction, particularly in light of recent incidents that have highlighted industry vulnerabilities. For instance, the tragic fire in Hong Kong exposed the severe consequences of using substandard materials such as unsafe netting, which failed to protect both workers and residents. The adoption of stringent safety measures is crucial in preventing such catastrophes, and wire steel, known for its superior strength and reliability, serves as a fundamental component in creating robust and secure structures.

Furthermore, initiatives like Harris County's new worksite safety policy, which mandates rest breaks during high temperatures, signify a growing recognition of worker welfare within the industry. Wire steel's durability not only ensures the structural integrity of construction projects but also contributes to safer work environments when paired with comprehensive safety regulations. As highlighted by the ongoing debates around labor shortages and safety gaps, integrating high-quality materials such as wire steel into the construction process is essential for fostering a culture of safety and accountability in an increasingly complex workforce landscape.

Environmental Benefits of Using Wire Steel in Sustainable Projects

Wire steel is increasingly recognized for its environmental benefits, particularly in sustainable construction and manufacturing projects. According to the World Steel Association, the production of steel from recycled sources can reduce energy consumption by up to 75%, significantly lowering greenhouse gas emissions. This is a crucial factor for industries striving to meet stricter sustainability targets and reduce their carbon footprint.

Moreover, wire steel is highly durable and recyclable, contributing to a circular economy. The Recycled Content in Construction report highlights that using wire steel not only minimizes waste but also promotes the reuse of materials in future projects, potentially saving up to 80% of the energy required for new steel production. As industries pivot towards more sustainable practices, the integration of wire steel becomes essential, driving innovation and resource efficiency while supporting eco-friendly initiatives in the construction sector.

Top 5 Reasons Why Wire Steel is Essential in Construction and Manufacturing

The bar chart above highlights the top five reasons why wire steel is essential in construction and manufacturing. Each reason is evaluated based on its importance rating, showcasing its significant role in promoting sustainability and efficiency in various projects.

Related Posts

-

2025 Top 5 Wire Steel Innovations Transforming the Industry

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Rod

-

Exploring the Growth of Industrial Steel Demand at China Import and Export Fair 2025

-

Exploring the Versatile Applications of Steel Wire Rod in Modern Construction and Manufacturing

-

The Ultimate Guide to Rolled Steel: Innovations, Applications, and Sustainability in 2023

-

The Advantages of Using Rolled Steel in Modern Construction and Design