What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

Steel bar stock is a fundamental material in the construction and manufacturing industries, providing the backbone for countless applications ranging from structural support to specialized machinery components. As a seasoned expert in metallurgical engineering, Dr. Emily Thompson emphasizes the versatility of steel bar stock, stating, “The unique properties of steel bar stock not only ensure durability but also allow for a remarkable range of customization in various industrial uses.”

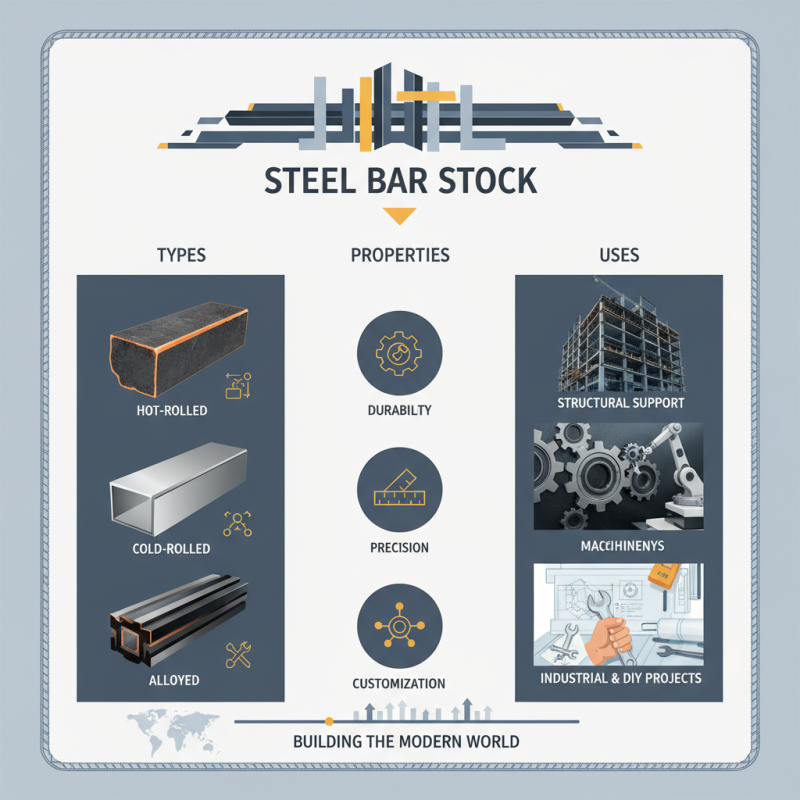

In this comprehensive guide, we will delve into the various types of steel bar stock available, including hot-rolled, cold-rolled, and alloyed options, each tailored to meet specific needs and standards. Understanding the distinctions and applications of these types is crucial for professionals who aim to enhance safety, efficiency, and performance in their projects. Whether you are a seasoned engineer, a construction manager, or a hobbyist, navigating the complexities of steel bar stock will empower you to make informed decisions that align with your requirements.

As we explore the properties, benefits, and uses of steel bar stock, it becomes clear that this material is not merely a commodity but a critical component in building the framework of our modern world.

Understanding Steel Bar Stock: Definition and Importance

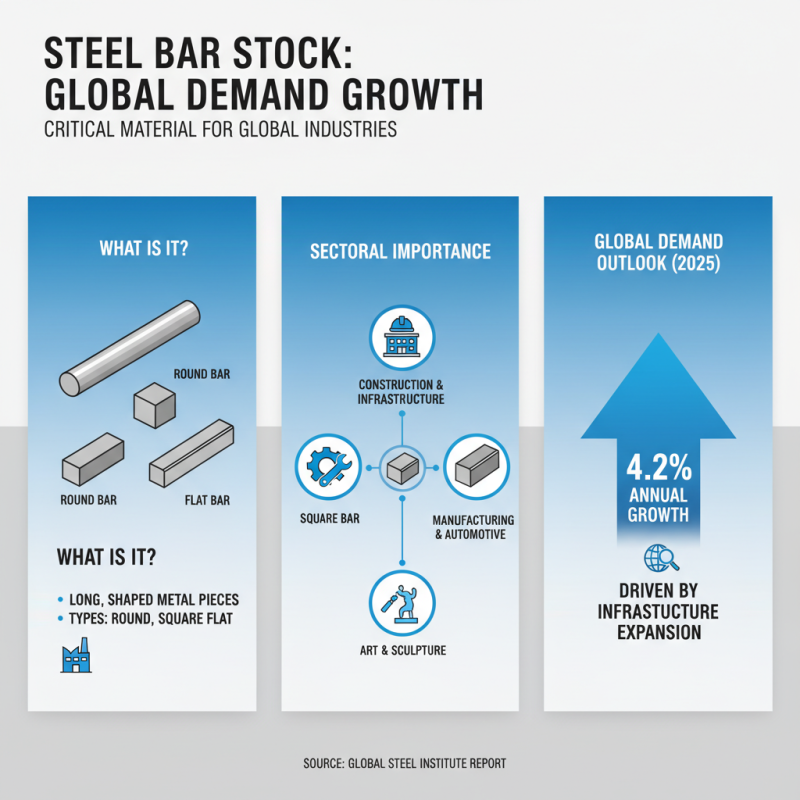

Steel bar stock is a fundamental material in various industries, serving as a critical component in construction, manufacturing, and even art. Defined as long, flat pieces of metal, steel bars are categorized into different types based on their shape, size, and properties, including round bars, square bars, and flat bars. According to a recent report by the Global Steel Institute, the demand for steel bar stock is projected to grow by approximately 4.2% annually through 2025, driven by the expansion of infrastructure projects worldwide.

Understanding the importance of steel bar stock is crucial for engineers and architects. These versatile materials are not only integral to the structural integrity of buildings and bridges but are also pivotal in the creation of various machinery parts. The American Institute of Steel Construction notes that using high-quality steel bar stock can enhance design flexibility and strength, making it a preferred choice in heavy construction and manufacturing applications. With its increasing role in sustainable construction methods and its recyclability, steel bar stock continues to be a vital material in modern engineering practices.

Different Types of Steel Bar Stock and Their Characteristics

Steel bar stock is a fundamental material in various construction and manufacturing applications. Understanding the different types and their characteristics is crucial for selecting the appropriate bar for your project. The most common types of steel bar stock include round bars, square bars, flat bars, and hexagonal bars, each serving distinct purposes.

Round bars are versatile and often used in machining and fabrication. Square bars offer excellent strength and are ideal for structural applications, while flat bars are perfect for creating brackets and supports. Hexagonal bars are frequently utilized in making fasteners and specialized components.

When choosing steel bar stock, consider the specific requirements of your project, including load-bearing capacity, corrosion resistance, and machining characteristics. It’s also essential to match the steel grade with your application's temperature and environmental conditions.

Tips: Always consult with a materials specialist to ensure you’re choosing the right type of steel bar. Additionally, consider the treatment processes available, such as cold drawing or heat treatment, which can enhance the performance of the steel according to your needs. Keep in mind the thickness and length required for your application to minimize waste and maximize efficiency.

Common Uses of Steel Bar Stock in Construction and Industry

Steel bar stock plays a crucial role in both construction and various industries, offering

versatility and reliability for numerous applications. In construction, steel bars are primarily used as reinforcement in concrete structures,

providing the necessary tensile strength to withstand heavy loads and environmental factors.

Commonly referred to as rebar, these bars come in different grades and sizes, making them suitable

for everything from residential buildings to bridges and highways.

In addition to construction, steel bar stock is widely utilized in manufacturing processes. It serves as a foundational material for producing components such as beams, columns, and frames.

Industries like automotive and aerospace rely on steel bar stock for crafting parts that demand

durability and precision. Furthermore, it’s often employed in the creation of custom machinery, offering

manufacturers the adaptability needed to tailor components to specific requirements.

Tips: When selecting steel bar stock, consider the specific application and loading requirements.

Always consult with structural engineers to determine the appropriate grade and size. Additionally,

keep in mind the environmental conditions the steel will face;

corrosion-resistant options may be necessary for outdoor or high-humidity applications.

Manufacturing Processes for Steel Bar Stock

Steel bar stock is a fundamental material used across various industries, and understanding its manufacturing processes is crucial for optimizing its applications. The production of steel bar stock typically begins with the selection of raw materials, predominantly iron ore, which is processed in a blast furnace to create molten steel. This steel is then cast into large molds, forming billets or blooms, which serve as the primary form for further processing.

After solidification, these billets undergo hot working processes, such as forging or rolling, where they are heated and shaped into long bars. Hot rolling is particularly common, as it allows for the manipulation of steel at temperatures above its recrystallization point, facilitating changes in shape and size while also improving the material's mechanical properties. Following the hot working stage, additional treatments such as cold drawing—or further rolling at room temperature—may be applied to enhance dimensional accuracy and surface finish.

Each of these processes contributes to the versatility of steel bar stock, making it suitable for various applications, from constructing buildings and bridges to manufacturing machinery and tools.

Choosing the Right Steel Bar Stock for Your Project Needs

When choosing the right steel bar stock for your project needs, it’s essential to consider several key factors that will influence both performance and durability. First, identify the specific type of steel bar that suits your application. Options include hot-rolled, cold-rolled, stainless steel, and alloy steel bars, each offering distinct properties. Hot-rolled bars are generally tougher and used for structural applications, while cold-rolled bars provide better precision and finish, making them suitable for detailed work.

Next, evaluate the dimensions and weight of the steel bar stock required for your project. Thickness, width, and length will affect not only the structural integrity of your project but also ease of handling during installation. Additionally, analyzing the environmental conditions your project will face can guide your choice; for example, stainless steel is ideal for corrosive environments. Ultimately, a thorough understanding of these elements will help you select the appropriate steel bar stock that meets your project’s requirements effectively.

What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

| Type of Steel Bar | Dimensions (inches) | Weight per Foot (lbs) | Common Uses |

|---|---|---|---|

| Mild Steel Round Bar | 1.00 x 1.00 | 2.67 | Construction, Manufacturing |

| Reinforcement Bar (Rebar) | #4 (1/2) | 0.668 | Concrete Reinforcement |

| Square Steel Bar | 2.00 x 2.00 | 5.11 | Structural Elements |

| Flat Steel Bar | 3.00 x 0.25 | 1.75 | Fabrication, Brackets |

| Steel I-Beam | 6 x 6 | 10.2 | Load Bearing Structures |

Related Posts

-

How to Select the Best Bar Steel for Your Construction Needs

-

The Ultimate Guide to Rolled Steel: Innovations, Applications, and Sustainability in 2023

-

Exploring the Growth of Industrial Steel Demand at China Import and Export Fair 2025

-

The Versatile Applications of Stainless Steel Wire Rod in Modern Industries

-

Understanding Cold Drawn Steel Bar: Characteristics, Applications, and Benefits

-

Innovative Uses of i Steel Bar in Modern Construction Techniques