Why Steel Bar is Essential for Construction and Its Impact on Structural Integrity

In the realm of construction, steel bars play a pivotal role in ensuring structural integrity and safety. As a fundamental component of reinforced concrete, steel bars, commonly known as rebar, provide the tensile strength necessary to withstand various loads and stresses experienced by buildings and infrastructure. Renowned structural engineer Dr. Emily Carter emphasizes the importance of this material, stating, "Steel bars are the backbone of modern construction, enabling structures to endure both gravity and dynamic forces."

The utilization of steel bars not only enhances the durability of a construction project but also contributes to the economic efficiency of building processes. With advancements in technology and engineering practices, the use of high-quality steel bars has become essential in designing structures that are resilient and long-lasting. Recognizing the crucial impact of steel bars on overall project outcomes underscores their vital role in the construction industry and highlights the need for continued innovation and excellence in this field.

Importance of Steel Bar in Construction Projects

Steel bars, commonly known as rebar, play a crucial role in reinforcing concrete structures, enhancing their strength and durability. According to a report by the World Steel Association, approximately 1.6 billion tons of steel were used in construction globally in 2020, with rebar constituting a significant portion of that demand. One of the essential functions of steel bars in construction projects is to resist tensile forces, which concrete alone cannot withstand. This combination promotes structural integrity, allowing buildings, bridges, and other infrastructures to endure various stress factors, including environmental conditions and heavy loads.

The importance of steel bars is further underscored in the context of safety and longevity. The American Concrete Institute (ACI) states that proper reinforcement can increase a structure's lifespan by effectively managing stresses induced during usage and environmental changes. Moreover, the integration of high-quality steel bars can minimize the risk of structural failure dramatically, which is critical given that construction accidents often stem from inadequate reinforcement. As construction standards evolve, the emphasis on using reliable materials like steel bars continues to grow, illustrating their indispensable role in ensuring the resilience and safety of modern infrastructures.

Role of Steel Bar in Enhancing Structural Integrity

Steel bars, commonly known as rebar, play a crucial role in enhancing the structural integrity of various construction projects. According to a report by the World Steel Association, steel reinforcement bars increase concrete's tensile strength, allowing for better load-bearing capabilities essential for high-rise buildings, bridges, and infrastructure projects. When embedded within concrete, rebar combats tensile forces that concrete alone cannot withstand, effectively preventing cracking and structural failure over time.

In addition, the use of steel bars has a significant impact on the lifespan and durability of structures. A study published by the American Concrete Institute highlights that the incorporation of rebar can extend the lifespan of concrete structures by up to 50%. This increase in longevity means reduced maintenance costs and fewer resources expended in repairs, making steel bars a cost-effective solution in the long run. Moreover, the adaptability of steel allows for the creation of innovative designs, which can significantly contribute to the aesthetic and functional qualities of construction projects while ensuring safety and reliability.

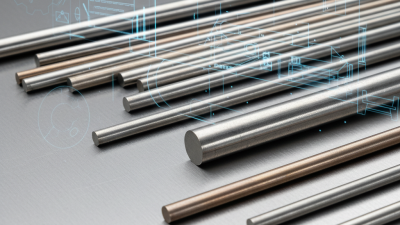

Types of Steel Bars Used in Construction

When it comes to construction, the choice of materials significantly influences the overall quality and safety of structures.

Steel bars, commonly known as reinforcing bars or rebar, are pivotal in providing tensile strength and ensuring the durability of concrete structures. In the construction industry, several types of steel bars are utilized, each tailored for specific applications and environments.

The most widely used steel bars include Mild Steel Bars, High Strength Deformed Bars (HYSD), and Stainless Steel Bars. Mild Steel Bars are known for their malleability and ductility, making them ideal for small-scale constructions. According to industry reports, Mild Steel constitutes about 40% of the total steel consumption in construction. High Strength Deformed Bars, on the other hand, offer enhanced tensile strength due to their ribbed surface, significantly improving grip with concrete. This type of bar is increasingly used, representing over 50% of the steel used in major infrastructure projects due to its superior load-bearing capacity.

Furthermore, Stainless Steel Bars play a crucial role in construction environments vulnerable to corrosion. Though they account for a smaller fraction of the total usage—approximately 5%—their importance cannot be overlooked, especially in coastal structures or chemical plants. The demand for corrosion-resistant materials is projected to grow by 4% annually, emphasizing the need for innovative solutions in construction to enhance structural integrity and longevity.

Advantages of Using Steel Bar for Load-Bearing Structures

Steel bars, often referred to as rebar, play a crucial role in the construction of load-bearing structures due to their exceptional strength and durability. According to the World Steel Association, steel has a tensile strength that is approximately five times greater than that of standard concrete, making it an ideal material for reinforcing concrete under tension. The integration of steel bars in concrete structures significantly enhances their structural integrity, allowing buildings and bridges to withstand various loads, from the weight of the structure itself to additional live loads such as occupants and furniture.

One of the key advantages of using steel bar in construction is its ability to absorb energy and deform without breaking. The American Concrete Institute reports that structures reinforced with steel bars have shown to have improved resilience during seismic events, effectively preventing catastrophic failures. Furthermore, steel's ductility contributes to the longevity of structures; it can endure considerable stress, which helps mitigate cracking and collapsing under pressure. Additionally, the recycling aspect of steel also aids in maintaining sustainability; around 85% of steel is recycled after its initial use, reducing the overall environmental impact of construction projects while ensuring a reliable material for load-bearing applications.

Environmental and Economic Impact of Steel Bar in Construction Industry

The construction industry significantly benefits from the use of steel bars, both environmentally and economically. Steel bars, known for their strength and durability, help reduce the overall material requirements by allowing for thinner designs and minimizing waste. This efficient usage of resources contributes to lower carbon emissions during production and transportation. Additionally, opting for steel rebar promotes recycling, as steel can be reused multiple times without losing its inherent properties, further diminishing its environmental footprint.

Tips for sustainable practices include sourcing steel from local suppliers to minimize transportation emissions and choosing recycled steel bars whenever possible. Emphasizing sustainability not only benefits the planet but can also lead to cost savings in material sourcing. Moreover, adopting efficient construction techniques can lead to significant reductions in waste, ultimately enhancing the economical use of steel in projects.

Economically, steel bars provide long-term value to construction projects. Their resistance to environmental factors reduces maintenance costs and prolongs the lifespan of structures. Investing in robust materials like steel not only secures structural integrity but also enhances safety, making it a prudent choice for developers and builders alike. As the demand for resilient infrastructure grows, leveraging steel's advantages will foster a more sustainable and economically viable construction industry.

Impact of Steel Bar Usage in the Construction Industry

Related Posts

-

How to Select the Best Bar Steel for Your Construction Needs

-

2025 Top 5 Wire Steel Innovations Transforming the Industry

-

2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations

-

Exploring the Growth of Industrial Steel Demand at China Import and Export Fair 2025

-

How to Select the Right Bar Steel for Your Construction Projects

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Rod