Understanding Different Stainless Steel Grades and Their Applications

In the world of materials science and engineering, understanding the various stainless steel grades is crucial for selecting the appropriate type for specific applications. Stainless steel, known for its corrosion resistance, durability, and aesthetic appeal, comes in numerous grades, each designed to meet unique performance criteria. According to John Smith, a renowned metallurgical expert, "Choosing the right stainless steel grade is not just about performance; it's about ensuring the longevity and reliability of the end product." This statement encapsulates the essence of why knowledge about stainless steel grades is essential for industries ranging from construction to medical devices.

Different stainless steel grades are tailored to various environments and operational challenges. For example, while some grades are optimal for high-temperature applications, others are better suited for environments prone to chemical exposure. Understanding these distinctions can significantly impact the efficacy and cost-effectiveness of a project. As industries evolve and new technologies emerge, the need for experts who comprehend the intricacies of stainless steel grades becomes increasingly vital. In this exploration, we will delve into the characteristics of different stainless steel grades, their applications, and how they can be leveraged to meet the varying demands of modern engineering challenges.

Overview of Stainless Steel: Definition and Classification

Stainless steel is a versatile alloy primarily composed of iron, chromium, and other elements that enhance its properties. Defined by its resistance to corrosion and staining, stainless steel is categorized into various grades, each tailored for specific applications. The classification is typically based on the microstructure, which includes austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steels. For instance, austenitic stainless steels, often designated as 300 series, contain higher amounts of nickel and chromium, which provide exceptional corrosion resistance and formability. According to industry reports, over 70% of stainless steel produced globally is austenitic, highlighting its dominance in industries ranging from food processing to architecture.

The grading system for stainless steel also takes into account the specific alloying elements that can significantly affect performance. Ferritic stainless steels, which typically contain 10.5% to 27% chromium, exhibit good resistance to stress corrosion and are often used in automotive applications and kitchenware. Meanwhile, martensitic grades, characterized by high strength and hardness after heat treatment, are commonly employed in manufacturing cutlery and surgical instruments. Research from the International Stainless Steel Forum indicates that the demand for these specialized grades continues to rise, particularly in sectors prioritizing durability and longevity. The ability to classify stainless steel into specific grades allows industries to select the appropriate type for their needs, ensuring both functionality and safety in their applications.

The Chemistry Behind Stainless Steel: Key Alloying Elements

Stainless steel is renowned for its corrosion resistance and strength, properties that are largely derived from the specific alloying elements it contains. The primary alloying element in stainless steel is chromium, which must be present in a minimum amount of 10.5%. Chromium reacts with oxygen in the environment to form a thin, protective oxide layer on the surface of the steel. This passive film is what gives stainless steel its name and helps to prevent rust and corrosion, making it suitable for a wide range of applications, from kitchen appliances to industrial equipment.

In addition to chromium, other elements such as nickel, molybdenum, and manganese play crucial roles in determining the characteristics of different stainless steel grades. Nickel, for example, enhances the toughness and ductility of the steel, as well as increasing its overall resistance to corrosion. Molybdenum further improves corrosion resistance, particularly in highly acidic or chlorinated environments. Manganese also contributes to strength and hardenability. The combination and proportions of these alloying elements are carefully selected to tailor the properties of stainless steel for specific applications, ensuring performance and longevity across various environments and conditions.

Understanding Different Stainless Steel Grades and Their Applications

| Stainless Steel Grade | Alloying Elements | Corrosion Resistance | Common Applications |

|---|---|---|---|

| 304 | 18% Cr, 8% Ni | Good | Food processing, kitchen equipment |

| 316 | 16% Cr, 10% Ni, 2% Mo | Excellent | Marine environments, chemical processing |

| 430 | 16% Cr | Moderate | Automotive trim, appliances |

| 2205 | 22% Cr, 5% Ni, 3% Mo | Very Good | Oil and gas, desalination plants |

| 254SMO | 20% Cr, 18% Ni, 6% Mo | Outstanding | Wastewater treatment, marine environments |

Comparative Analysis of Common Stainless Steel Grades and Their Properties

When evaluating stainless steel grades, it is crucial to understand the properties that distinguish each type and its suitability for various applications. The most common grades include 304, 316, and 430, each characterized by their unique composition and corrosion resistance.

Grade 304, often referred to as the standard grade, contains a high percentage of chromium and nickel, providing superior rust resistance and maintaining strength at high temperatures. This makes it ideal for kitchen equipment, food processing, and chemical industries.

In contrast, grade 316 is another widely utilized stainless steel known for its added molybdenum content, which enhances its resistance to pitting and crevice corrosion in chloride environments. Because of these properties, grade 316 is preferred in marine applications, medical devices, and pharmaceuticals, where exposure to aggressive environments is common.

On the other hand, grade 430, a ferritic stainless steel, offers adequate corrosion resistance at a lower cost, making it suitable for applications like automotive trims, kitchen utensils, and appliances where high strength and low oxidation are necessary but less corrosion resistance is acceptable. Each stainless steel grade serves distinct roles based on these comparative properties, making the choice critical depending on the specific requirements of the application.

Applications of Stainless Steel in Different Industries: A Practical Guide

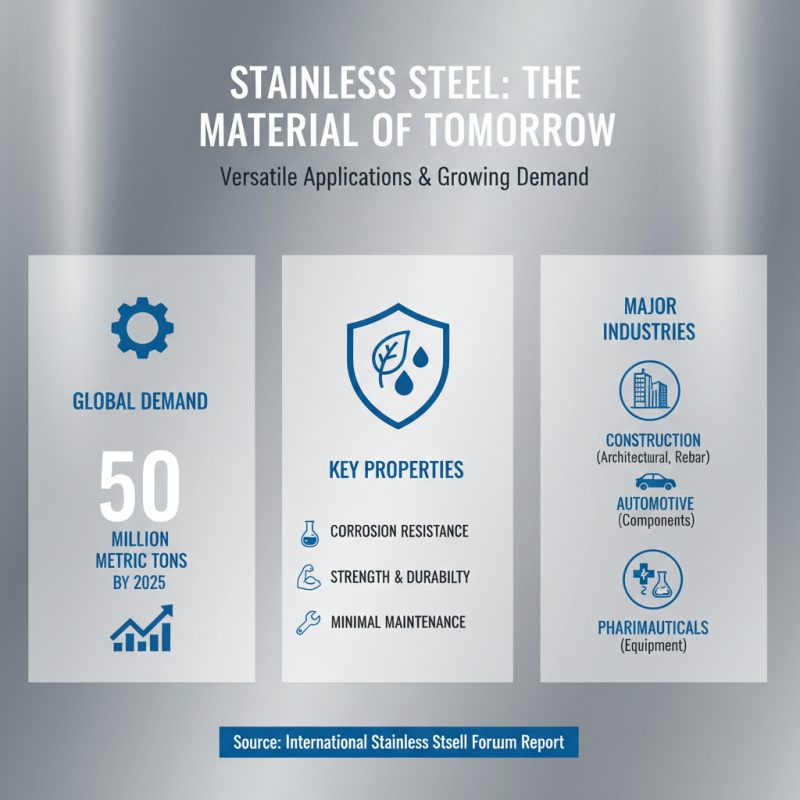

Stainless steel is a versatile material utilized across various industries due to its excellent corrosion resistance, strength, and durability. According to a report by the International Stainless Steel Forum, the global demand for stainless steel is projected to reach 50 million metric tons by 2025, driven by its applications in sectors such as construction, automotive, and pharmaceuticals. In construction, stainless steel is favored for architectural frameworks, fixtures, and reinforcement bars, owing to its longevity and minimal maintenance requirements. For instance, its application in bridges and high-rise buildings not only improves structural integrity but also enhances aesthetic appeal, allowing for innovative designs that stand the test of time.

The automotive industry also heavily relies on stainless steel, particularly for exhaust systems, fuel tanks, and structural components, where its combination of strength and weight savings contributes to fuel efficiency. A report from MarketsandMarkets indicates that the automotive stainless steel market is expected to grow at a CAGR of 6.3% from 2021 to 2026, reflecting the ongoing push for sustainability and emissions reduction. Furthermore, in the pharmaceutical industry, stainless steel is employed in manufacturing equipment and storage tanks due to its hygienic properties and ability to withstand sterilization processes. This adaptability across different sectors highlights stainless steel's critical role in modern industry, offering solutions that meet both functionality and regulatory requirements.

Trends in Stainless Steel Usage: Growth and Sustainability Factors

The stainless steel industry is experiencing notable trends driven by both growth and sustainability concerns. As various sectors expand, the demand for diverse stainless steel grades increases, particularly due to their enhancing properties such as corrosion resistance and durability. This evolution is not just a response to market needs but also a reflection of a broader commitment to sustainable practices across industries. Manufacturers are increasingly focusing on recycling and using eco-friendly production methods, which contribute to reduced environmental impact.

Tips for embracing sustainability in your stainless steel projects include opting for recycled stainless steel whenever possible, as it consumes less energy and resources compared to virgin materials. Additionally, consider implementing innovative designs that extend the life cycle of products, minimizing waste and supporting sustainability goals.

Furthermore, as industries shift toward sustainable materials, it’s essential to stay informed about advancements in stainless steel technologies and innovations. Collaborative efforts among professionals, suppliers, and recyclers are vital for fostering a circular economy, ensuring that stainless steel not only meets application requirements but also adheres to ecological responsibility. By keeping abreast of these trends, businesses can better position themselves in a competitive marketplace while contributing positively to environmental sustainability.

Stainless Steel Grades and Their Applications

Related Posts

-

How to Choose the Right Stainless Steel Grades for Your Project

-

Understanding the Benefits of Using Cold Drawn Steel Bars in Modern Construction

-

Top 5 Applications of Wire Rods in Modern Manufacturing You Didn't Know About

-

Understanding Hot Rolled Steel: Innovations, Processes, and Applications in Modern Industry

-

Top 10 Benefits of Using Cold Drawn Steel Bars in Construction Projects

-

Top 10 Steel Rod Specifications You Need to Know for Your Projects