How to Select the Right Bar Steel for Your Construction Projects

Selecting the right bar steel for construction projects is a critical decision that can significantly impact the safety, durability, and overall success of a structure. According to the World Steel Association, steel production reached approximately 1.9 billion metric tons in 2022, with bar steel representing a substantial portion of this output. The demand for bar steel in construction has surged as the industry seeks to enhance structural integrity while optimizing material costs. Understanding the various properties of bar steel—such as tensile strength, ductility, and corrosion resistance—is essential for engineers and architects when determining the most suitable material for their specific project needs.

In recent years, industry reports have highlighted the increasing use of advanced bar steel grades that offer improved performance and resilience. For instance, a document from the American Society for Testing and Materials (ASTM) indicates that the correct selection of bar steel can reduce construction costs by up to 20% while prolonging the lifespan of the structure. As urbanization accelerates and infrastructure demands rise, construction professionals must be equipped with the knowledge of the most current bar steel options and their applications. This comprehensive understanding not only ensures compliance with regulatory standards but also promotes sustainable building practices by reducing waste and resource consumption.

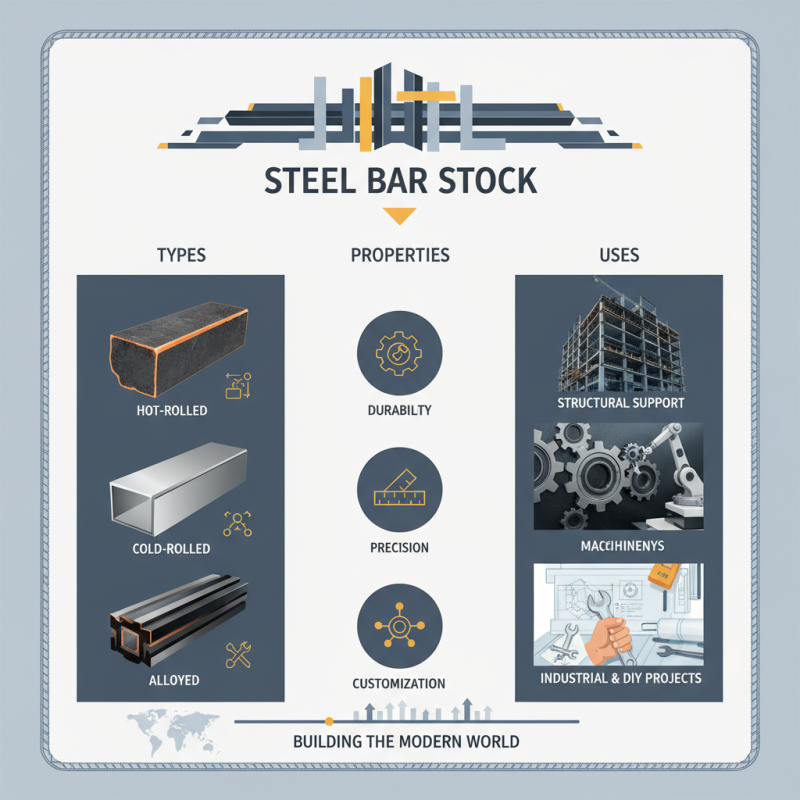

Understanding Bar Steel Types and Specifications

When it comes to selecting the right bar steel for your construction projects, understanding the various types and specifications is crucial. Bar steel is available in several forms, including hot-rolled and cold-rolled, each with distinct properties that affect their application. Hot-rolled bars are typically produced at high temperatures, leading to a more malleable material that's easier to shape for structural applications. Conversely, cold-rolled bars undergo a more precise manufacturing process, resulting in enhanced surface finish and tighter tolerances, which can be beneficial for critical projects.

Tips: Always assess your project requirements first. For structural frames and support, hot-rolled bars may be the preferred choice due to their strength and versatility. However, if your project demands a higher level of precision and appearance, consider cold-rolled options. Additionally, pay attention to the steel grade; options like ASTM A615 or A706 might be suitable depending on the tensile strength and ductility needed for your specific application.

Another important aspect to consider is the diameter and length of the bar steel. Different diameters serve specific structural functions, such as reinforcement in concrete or as anchor points. Longer bars may require careful handling and transportation planning to ensure they arrive on-site in optimal condition. Be sure to consult with your design team to specify dimensions that meet structural engineering requirements while accommodating logistical challenges.

Bar Steel Types Comparison for Construction Projects

Key Factors to Consider When Selecting Bar Steel

When selecting bar steel for construction projects, several key factors must be considered to ensure that the material meets the specific structural requirements and environmental conditions of the project. One of the primary considerations is the steel grade, which is determined by the yield strength and tensile strength of the steel. Higher-grade steel usually offers better durability and performance, making it suitable for structures that demand resilience against heavy loads and extreme conditions. Understanding the project's load requirements can help determine the appropriate grade of steel to use.

Another crucial factor is the bar size and shape. The dimensions of bar steel play a significant role in its structural capabilities, as well as its compatibility with other materials in the construction. It's important to evaluate the design specifications and structural calculations to select the right size that can support the intended loads without compromising safety. Additionally, corrosion resistance is a vital consideration, especially in environments prone to moisture or harsh conditions. Choosing bar steel with suitable coatings or treatments can extend the lifespan of the steel and reduce maintenance costs over time. By carefully assessing these factors, one can make an informed decision that enhances the overall integrity and performance of the construction project.

Common Applications of Bar Steel in Construction

Bar steel plays a crucial role in various construction applications, owing to its strength, versatility, and durability. One of the most common uses of bar steel is in reinforcement for concrete structures, where it provides the necessary tensile strength to withstand stress and load. Rebar, a type of bar steel, is embedded within concrete to improve its overall structural integrity. Whether it’s in residential buildings, bridges, or high-rise towers, rebar supports and stabilizes these constructions against dynamic forces like wind and earthquakes.

Additionally, bar steel is often utilized in the fabrication of structural steel components, such as beams and columns, which are essential for forming the skeleton of large buildings. These components, often shaped from hot-rolled or cold-rolled bar steel, offer significant load-bearing capacities and allow for flexible design options in architecture. Beyond structural applications, bar steel is also found in the construction of temporary structures, scaffolding, and reinforcement cages, providing essential support during the construction process. Each application highlights the necessity of selecting the appropriate type of bar steel to ensure safety and efficiency in construction projects.

How to Assess Bar Steel Quality and Standards

When selecting bar steel for construction projects, assessing the quality and standards of the material is crucial to ensure safety and longevity. Start by examining the specifications and certifications associated with the steel. Look for compliance with national and international standards such as ASTM or ISO, which indicate that the steel has undergone rigorous testing and meets the required mechanical properties. The certification can provide insight into the material's strength, ductility, and resistance to corrosion—key factors for determining its suitability for a specific project.

In addition to certifications, consider the manufacturing processes involved in producing the bar steel. Quality control during production plays a significant role in the final attributes of the steel. Investigate the methods used, such as hot-rolling or cold-working, as these processes can affect the steel's microstructure and overall performance. Moreover, examining samples through testing methods like tensile tests or impact tests will provide tangible evidence of the steel's quality. Ultimately, ensuring that both the sourcing and manufacturing practices adhere to high standards will lead to selecting the best bar steel for your construction needs.

How to Select the Right Bar Steel for Your Construction Projects - How to Assess Bar Steel Quality and Standards

| Criteria | Description | Standard Specification | Typical Applications |

|---|---|---|---|

| Material Grade | Indicates the strength and chemical composition | ASTM A615 | Reinforced concrete structures |

| Yield Strength | The minimum stress at which material begins to deform | Grade 60 (414 MPa) | Building frames and infrastructures |

| Ductility | The ability to deform under tensile stress | ASTM A706 | Seismic-resistant structures |

| Surface Finish | The smoothness and cleanliness of the bar surface | Clean and free of rust | Welding and bonding applications |

| Manufacturing Process | Method used to produce the steel bars | Hot Rolled vs. Cold Rolled | Varied structural applications |

Cost Considerations for Bar Steel in Construction Projects

When selecting bar steel for construction projects, cost considerations play a crucial role in decision-making. The price of bar steel can fluctuate based on various factors, including market demand, quality, and the type of steel required for specific applications. Understanding the different grades of bar steel and their associated costs is essential. Higher-grade steels may offer superior strength and durability but can come with a significantly higher price tag.

Budget constraints are often a determining factor, necessitating careful evaluation of the balance between cost and performance.

Additionally, the sourcing and quantity of bar steel can impact overall project costs. Purchasing in bulk might yield discounts, but it is important to consider storage and material handling expenses. Transportation costs should also be factored into the budget, as they can vary depending on the distance from suppliers and current fuel prices. By analyzing the total cost of ownership, including potential waste and rework, construction managers can make informed decisions that align with both their financial constraints and the project's structural requirements.

Related Posts

-

How to Select the Best Bar Steel for Your Construction Needs

-

What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

-

The Versatile Uses of Steel Wire Rod in Modern Construction and Manufacturing

-

Understanding the Benefits of Using Cold Drawn Steel Bars in Modern Construction

-

Top 5 Applications of Wire Rods in Modern Manufacturing You Didn't Know About

-

Exploring the Future of Carbon Steel: Insights from the 138th Canton Fair 2025 in China