Understanding Hot Rolled Sheet: Benefits, Applications, and Key Differences

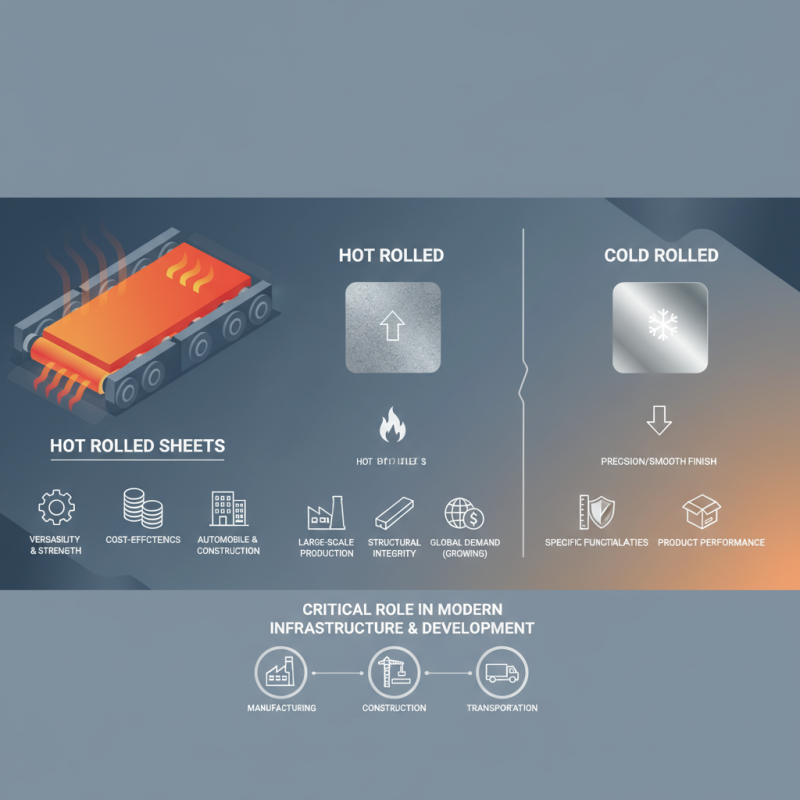

Hot rolled sheets are integral components in various industries, renowned for their versatility and strength. As per a report by Smithers Pira, the global demand for hot rolled steel is expected to grow significantly, driven by the automobile and construction sectors, which utilize hot rolled sheets for their optimal balance of formability and structural integrity. This type of steel is produced through the hot rolling process, where steel is heated above its recrystallization temperature and then rolled to achieve desired thickness and dimensions.

One of the key advantages of hot rolled sheets is their cost-effectiveness. According to industry analysts, the production of hot rolled sheets is generally less expensive compared to cold rolled sheets due to lower processing costs. Additionally, the hot rolling process allows for the quick shaping of large quantities of steel, making it an attractive option for manufacturers who require efficient and large-scale production methods. The applications of hot rolled sheets span a wide array of industries, including manufacturing, construction, and transportation, highlighting their critical role in modern infrastructure and development.

In understanding the benefits and applications of hot rolled sheets, it is essential to recognize the differences between hot rolled and cold rolled products. While both serve vital purposes, the characteristics of hot rolled sheets—such as their surface finish and mechanical properties—set them apart for specific functionalities. This distinction not only affects manufacturing choices but also influences product performance in real-world applications.

Understanding the Basics of Hot Rolled Sheet: Definition and Process

Hot rolled sheet is a type of metal product that is created through a specific manufacturing process involving high temperatures. During the hot rolling process, metal, typically steel, is heated to over 1,700°F, which allows it to become malleable. Once heated, the metal is passed through rollers to achieve the desired thickness and shape. This procedure not only improves the material's mechanical properties but also allows for the production of large volumes of sheets quickly and efficiently.

One of the major benefits of hot rolled sheets is their cost-effectiveness. The hot rolling process requires less energy than cold rolling, making it a cheaper option for producing metal sheets. Additionally, because the sheets remain relatively soft after the process, they are easier to work with in various applications. Industries widely use hot rolled sheets in construction, automotive manufacturing, and fabrication work due to their durability and versatility.

**Tip:** When selecting hot rolled sheets for a project, consider the finish and surface conditions; while hot rolled sheets often possess a rough finish, they can be further processed if a smoother surface is required. Additionally, always assess the material's specifications to ensure it meets the application's strength and flexibility requirements.

Benefits and Applications of Hot Rolled Sheet

Key Benefits of Hot Rolled Sheets in Various Industries

Hot rolled sheets are widely recognized for their versatility and durability, making them essential components in various industries. One of the primary benefits of hot rolled sheets is their ability to maintain structural integrity under harsh conditions. This makes them ideal for construction applications, where strength and stability are paramount.

The manufacturing process involves rolling the metal at high temperatures, which not only enhances its workability but also improves its mechanical properties, providing optimal performance in applications such as beams, columns, and other structural elements.

In addition to construction, hot rolled sheets find extensive use in the automotive and manufacturing sectors. Their malleability allows for easy shaping and forming, which is crucial for producing complex parts and components.

The dimensional accuracy provided through hot rolling also contributes to the production of high-quality products that can withstand rigorous operational demands. Moreover, the cost-effectiveness of hot rolled sheets makes them a preferred choice for businesses looking to optimize their production processes while maintaining quality standards. This combination of benefits, including strength, flexibility, and economic efficiency, solidifies the importance of hot rolled sheets across diverse industrial applications.

Common Applications of Hot Rolled Sheets: From Construction to Manufacturing

Hot rolled sheets are pivotal in numerous industries due to their versatility and cost-effectiveness. These sheets, produced by rolling steel at high temperatures, are widely utilized in construction applications such as structural beams, roofing, and framing systems. According to a report by the World Steel Association, the construction sector accounted for 50% of global steel consumption in 2022, highlighting the significance of hot rolled sheets in supporting infrastructure development.

In manufacturing, hot rolled sheets serve as essential raw materials in various processes. They are commonly employed in the production of heavy machinery, automotive components, and appliances, where durability and strength are paramount. A recent market analysis indicates that the global market for hot rolled steel is expected to grow at a CAGR of 4.5% from 2023 to 2028, driven by rising demands from the automotive and construction sectors. This growth reflects the reliability of hot rolled sheets as manufacturers prioritize materials that can withstand high stress and perform effectively under various conditions.

Moreover, the adaptability of hot rolled sheets allows for their application in industries beyond construction and manufacturing, including shipbuilding and energy sectors. As infrastructure continues to expand and reshape, the demand for hot rolled sheets remains robust, underscoring their critical role in modern industry.

Understanding Hot Rolled Sheet: Benefits, Applications, and Key Differences

| Application | Description | Benefits | Typical Thickness (mm) |

|---|---|---|---|

| Construction | Used for structural shaping and fabricating frames for buildings and infrastructure. | High strength, cost-effective solution for large-scale projects. | 6 - 25 |

| Manufacturing | Used for producing tubes, pipes, and metal components. | Versatile and can be easily welded and formed. | 3 - 15 |

| Automotive | Used for making various structural and body components. | Provides necessary strength and reliability in vehicle assembly. | 1 - 10 |

| Shipbuilding | Used for hulls and structural components in ships. | Durable and resistant to harsh marine environments. | 8 - 20 |

| Energy | Used in power plants and renewable energy structures. | Supports the construction of robust energy infrastructure. | 5 - 15 |

Key Differences Between Hot Rolled and Cold Rolled Sheets

When discussing the key differences between hot rolled and cold rolled sheets, it's essential to recognize the distinct processes and resulting characteristics of each type. Hot rolling involves heating the metal above its recrystallization temperature and then shaping it, which allows for significant deformation. This method often results in a lower-cost product with improved workability. According to the World Steel Association, hot rolled products typically exhibit a lower yield strength, ranging from 200 to 250 MPa, and a higher ductility compared to their cold rolled counterparts, making them suitable for structural applications where formability is critical.

In contrast, cold rolling involves processing the material below its recrystallization temperature, which refines the grain structure and enhances the hardness and tensile strength of the sheets. Reports by the American Iron and Steel Institute indicate that cold rolled sheets can achieve yield strengths exceeding 350 MPa, making them preferable for precision applications that demand tighter tolerances and superior surface finish, such as automotive components and household appliances. This enhanced strength, however, comes at an increased production cost, which must be factored into decision-making when selecting the appropriate type of metal sheet for specific industrial applications.

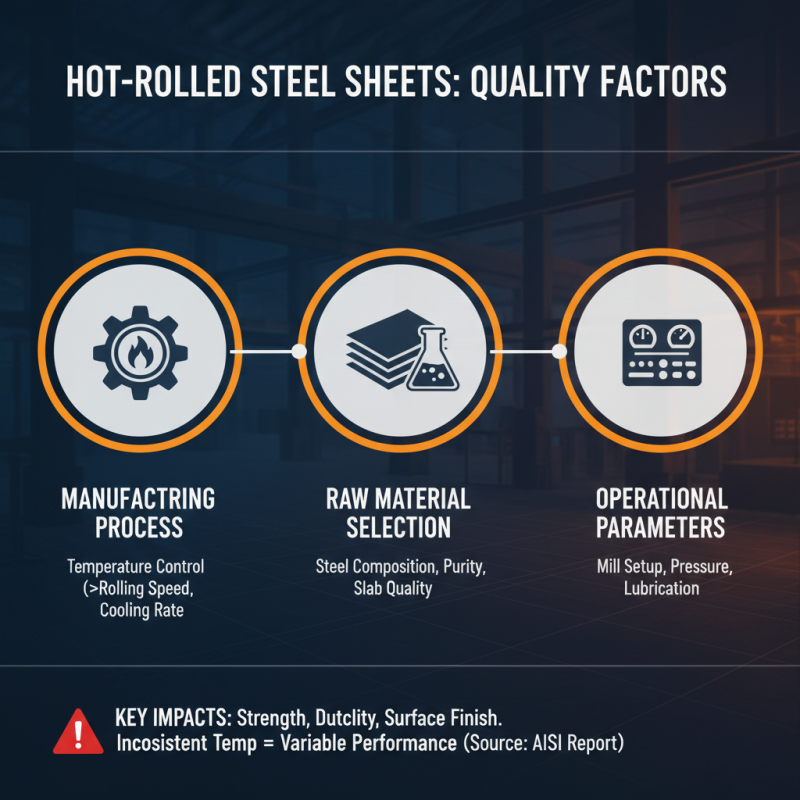

Factors Influencing the Quality of Hot Rolled Sheets and Their Performance

The quality of hot rolled sheets is primarily influenced by several factors including the manufacturing process, raw material selection, and operational parameters during production. During the hot rolling process, temperatures typically exceed 1,700°F (926°C), which allows metals to change shape without breaking. This high-temperature environment can lead to variability in the final product’s mechanical properties, including strength, ductility, and surface finish. According to a report by the American Iron and Steel Institute (AISI), inconsistencies in temperature control can cause significant performance differences in hot rolled sheets, affecting their suitability for various applications.

Careful selection of raw materials is also essential for producing high-quality hot rolled sheets. The chemical composition of the steel, including the levels of carbon, manganese, and phosphorous, can directly affect the sheet’s performance. Reports indicate that high-quality steel with well-controlled chemical compositions enhances the mechanical properties and reduces defects in the final product. For instance, steel with a lower sulfur content tends to offer better ductility and weldability, making it more suitable for structural applications.

Tips: Always ensure the hot rolled sheets meet industry standards by verifying the steel grades and required mechanical properties according to relevant specifications. Additionally, consider the intended application of the sheets to select the proper thickness and surface finish, as these factors can significantly impact performance in the field. Regular quality checks during the production process can help maintain consistency and minimize defects.

Related Posts

-

Understanding Hot Rolled Sheets Their Benefits and Applications in Modern Manufacturing

-

2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations

-

How to Find Reliable Steel Supply Sources for Your Projects

-

The Versatile Uses of Steel Wire Rod in Modern Construction and Manufacturing

-

Exploring the Versatile Applications of Steel Wire Rod in Modern Construction and Manufacturing

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Rod