10 Essential Tips for Choosing the Right I Steel Bar

Choosing the right I steel bar is crucial for construction projects. John Smith, a renowned industry expert, states, “Quality steel is the backbone of any solid structure.” Understanding the importance of selecting the best I steel bar can greatly impact durability and safety.

When selecting an I steel bar, consider its grade and specifications. Different projects require varying strength levels. For example, a bridge needs more robust bars than a residential building. Don’t overlook dimensions; the size affects load capacity. Measure precisely to avoid costly mistakes.

Furthermore, sourcing from reputable suppliers matters. Not all products meet industry standards. This choice ensures reliability and compliance. Reflect on past experiences when making this decision. Poor choices may lead to structural issues later. Balanced considerations can lead to successful construction outcomes with the right I steel bar.

Understanding Various Types of I Steel Bars and Their Applications

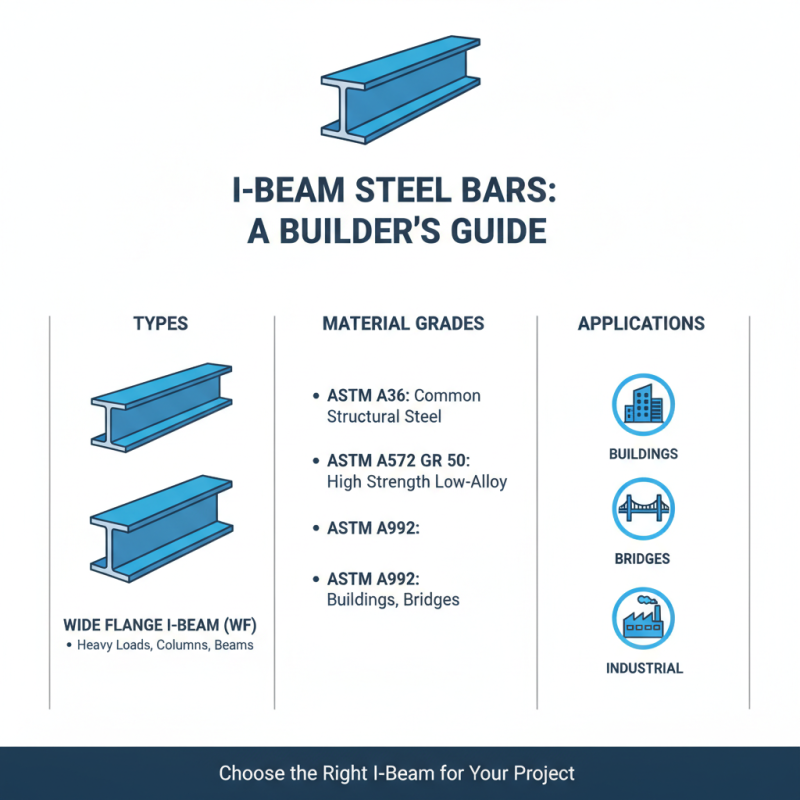

When selecting I steel bars, understanding the variety available is crucial. I steel bars, commonly used in construction, come in different profiles and grades. Each type has its specific application. For example, structural beams and columns often utilize wide flange I bars. These provide optimal strength for heavy loads.

On the other hand, standard I bars are prevalent in residential projects. They offer a balance between strength and weight. However, not all projects require the same specifications. Sometimes, a smaller bar might appear sufficient but could lack the necessary quality. It's essential to assess project needs deeply.

Consider the environment too. If exposed to moisture or chemicals, corrosion-resistant bars are recommended. Aesthetics might play a role as well. Yet, beauty shouldn't compromise safety. Reflect on your choices carefully. Make sure to consult with professionals who understand materials well. Their advice can guide you to the best fit for your projects.

Assessing Load Requirements and Structural Integrity for I Steel Bars

When selecting I steel bars, understanding load requirements is crucial. Each project has unique weight and stress factors. Structural integrity hinges on these computations. Start by calculating how much load the steel will bear. This assessment can prevent costly failures later. If your calculations are slightly off, the consequences could be severe.

Next, consider the specific dimensions of the I steel bar. Width and height directly impact strength. A larger beam might seem like a solution but can also weigh more. This added weight could necessitate a heavier frame. Adjusting dimensions can often solve structural issues. Aim for a balance that fits your project.

It's essential to consult local building codes as they can dictate requirements. Regulations vary, and what works in one area may not be valid in another. Ensuring compliance is an ongoing challenge. Checking your sources regularly might seem tedious but is vital for safety. Remember, every detail matters in structural design. Make mistakes, learn, and refine your approach along the way.

Evaluating Material Standards and Certifications for Quality Assurance

Choosing the right steel bar depends heavily on evaluating material standards and certifications. Quality assurance is key to ensuring durability and strength. According to industry reports, 70% of structural failures stem from poor-quality materials. It’s crucial to verify the certifications of the steel bars you plan to use. Look for standards like ASTM, ISO, or EN that guarantee quality.

A tip to consider is the certification label. It should not only indicate compliance but also detail the material grade. This information reflects the steel’s properties and suitability for your project. When assessing products, don't overlook the manufacturer’s reputation. Gathering reviews and feedback can provide insights into quality.

Understanding the specific needs of your project is essential. Different applications require different grades of steel. For example, construction projects may need higher tensile strength. Be cautious with the cheaper options on the market; they can compromise safety. Relying on verified data can streamline your selection process, but continual evaluation of your choices is equally important.

10 Essential Tips for Choosing the Right I Steel Bar - Evaluating Material Standards and Certifications for Quality Assurance

| Dimension | Material Standard | Certification | Strength (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| 10mm | ASTM A615 | ISO 9001 | 400 | 0.78 |

| 12mm | BS 4449 | ISO 14001 | 420 | 0.93 |

| 16mm | ASTM A996 | CE Marking | 460 | 1.58 |

| 20mm | ACI 318 | ASTM E1407 | 500 | 2.01 |

| 25mm | EN 10080 | ISO 45001 | 520 | 2.49 |

Considering Cost Factors and Budget Constraints for I Steel Bars

When selecting I steel bars, understanding cost factors is essential. Many buyers focus on material quality, but budgets often dictate choices. Prices can vary significantly based on size, grade, and supplier. A small error in estimating these elements can lead to overspending.

Consider material specifications carefully. Higher grades may offer improved strength but at a premium cost. A mismatch between project needs and material choice could result in unusable excess. Frequent price fluctuations in the market can also create challenges. Keep an eye on local supply and demand trends.

Finally, remember to factor in transportation costs. They can add substantially to the total expense. Comparing quotes from multiple suppliers is wise, but ensure you don’t compromise quality for savings. It's easy to get caught up in the numbers and overlook critical details. Balancing quality with budget constraints requires thoughtful consideration.

Choosing Reputable Suppliers and Manufacturers for Reliable Sourcing

When selecting steel bars, sourcing from reputable suppliers is crucial. A recent report by the World Steel Association highlights that 70% of structural failures can be traced back to material quality issues. This underscores the importance of ensuring reliable sourcing. Not all suppliers meet the rigorous standards necessary for high-quality steel. Hence, it’s vital to conduct thorough research.

Choosing a well-established manufacturer often leads to better materials. Industry data indicate that companies with a proven track record reduce supply chain risk by nearly 30%. Certifications like ISO 9001 can guide you to reputable suppliers. However, not every claim is verified. Be wary of overly glossy marketing materials that promise the world but lack transparency about their processes.

Engaging directly with suppliers can yield insights into their production practices. Ask about their sourcing methods and quality control measures. Visiting plants can also shed light on their operations. Many potential suppliers may promise high standards, yet their actual practices may not align. Always prioritize transparency and open communication. This reduces the likelihood of encountering subpar products later on.

Steel Bar Strength Comparison

Related Posts

-

How to Select the Right Bar Steel for Your Construction Projects

-

The Future of Hot Rolled Bars in Construction and Manufacturing Industries

-

The Best Types of Steel Bars for Construction and Their Benefits

-

Why Steel Bar is Essential for Construction and Its Impact on Structural Integrity

-

2026 Top Rolled Steel Trends Innovations and Applications in Industry

-

Exploring the Growth of Industrial Steel Demand at China Import and Export Fair 2025