How to Choose the Right Metal Bar for Your Project?

Choosing the right metal bar can significantly impact your project’s success. According to John Smith, a leading expert in the metal industry, “The right metal bar is crucial for structural integrity.” His insights provide a valuable perspective for anyone navigating material selection.

When selecting a metal bar, consider its properties. Different metals have varying strengths, weights, and corrosion resistance. Your project needs will dictate the best choice. Whether it's aluminum for a lightweight frame or steel for strength, knowing your requirements helps.

However, many overlook the importance of sourcing. Not all suppliers provide quality metal bars. Some might offer lower prices but compromise on durability. This decision can lead to future issues. Reflecting on these factors will guide you in choosing wisely. Selecting the right metal bar demands careful thought and consideration.

Understanding the Different Types of Metal Bars in Construction

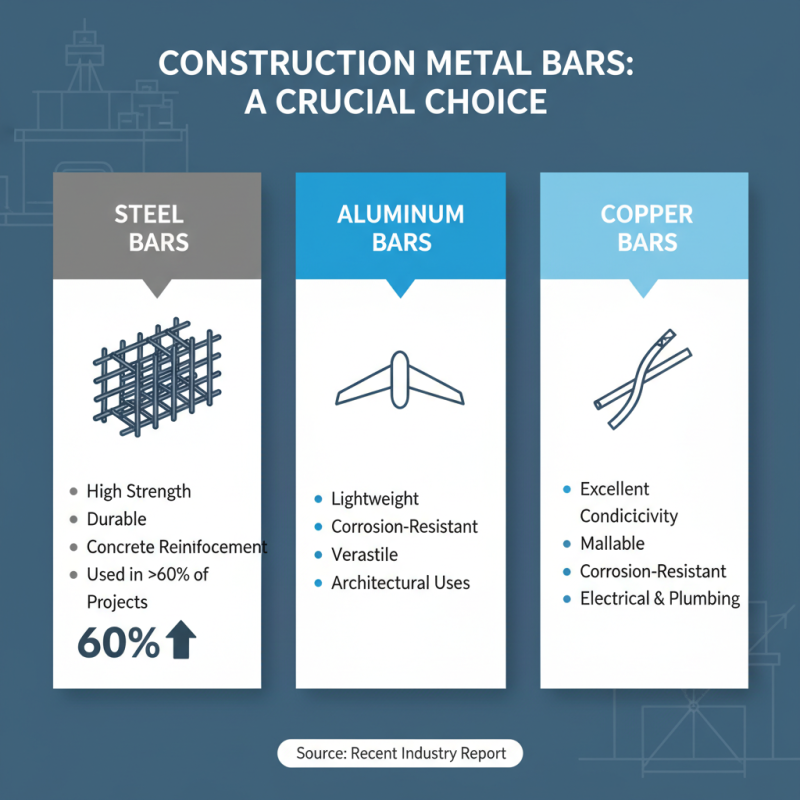

When it comes to construction, selecting the right metal bar is crucial. The most common types include steel, aluminum, and copper bars. Each type has unique properties that cater to different project needs. According to a recent industry report, over 60% of construction projects use structural steel due to its high strength and durability. Steel bars are essential for concrete reinforcement.

On the other hand, aluminum bars are favored for their lightweight and corrosion resistance. They are ideal for applications where weight savings are crucial, such as in aerial structures. Interestingly, the demand for aluminum is increasing. Recent statistics show a rising trend, with aluminum consumption in construction up by 15% over the last five years. This shift reflects the industry’s evolving preferences.

It’s important to evaluate the specific requirements of your project. A common mistake is choosing a bar that doesn't meet load specifications. For instance, opting for copper bars can lead to higher costs, despite their excellent conductivity. Often, projects exceed budgets due to improper material selection. Understanding the nuances of each type of bar can save time and resources, guiding you to make informed choices.

Key Properties of Metal Bars: Strength, Weight, and Corrosion Resistance

Choosing the right metal bar for your project isn’t always straightforward. Understanding the key properties is essential. Strength, weight, and corrosion resistance are vital factors. For instance, a report by the Metal Institute revealed that the yield strength for aluminum bars can reach up to 300 MPa, ideal for lightweight applications. Steel, with yield strengths often exceeding 250 MPa, is favored for heavy-duty tasks.

Weight considerations also play a significant role. Aluminum bars weigh about one-third of steel, making them suitable for applications where reducing weight is crucial. However, this comes at the cost of some strength. So, balancing these properties becomes a challenge. Additionally, corrosion resistance varies significantly. Stainless steel, for example, can resist aggressive environments, while regular carbon steel may corrode in just a few months if not properly treated.

It’s essential to evaluate the project's specific needs, such as exposure to elements. Some projects may require sacrificing weight for strength or vice versa. Understanding these compromises is key. It highlights the complexity of material selection, where no option is perfect. Avoiding a thorough assessment can lead to failures, compromising durability and performance.

Considerations for Choosing Metal Bars Based on Project Requirements

When choosing metal bars for a project, specific factors are essential. The type of metal impacts strength, weight, and cost. Consider if your project requires aluminum for its lightweight properties or steel for its strength. Each metal has unique characteristics that can affect your design.

Durability is key. Think about the environment where the metal bar will be used. Will it face moisture or harsh chemicals? Corrosion-resistant metals like stainless steel might be necessary in such cases. Remember, long-lasting materials can save money in the long run.

Tip: Always check material specifications before purchasing. Understand the tensile strength and yield point of the metals you consider. This can prevent issues during construction.

A common mistake is not factoring in the bar’s finish. Different finishes can affect the bar's appearance and functionality. This often gets overlooked but is crucial for aesthetic projects. Reflect on how the bar's surface may impact your design goals.

Tip: Get samples whenever possible. This can help you evaluate not just the look but also the feel of the materials. Sometimes, what seems perfect on paper may not suit your vision in reality.

How to Choose the Right Metal Bar for Your Project?

| Metal Type | Strength (MPa) | Weight (kg/m) | Corrosion Resistance | Cost per Meter ($) |

|---|---|---|---|---|

| Aluminum | 70 | 2.7 | Good | 2.50 |

| Steel | 250 | 7.85 | Fair | 1.50 |

| Stainless Steel | 500 | 8.0 | Excellent | 5.00 |

| Titanium | 900 | 4.5 | Outstanding | 20.00 |

Cost Analysis: Comparing Price Per Ton for Various Metal Bar Types

When considering metal bars for your project, price per ton plays a crucial role. Steel is often the most cost-effective choice, averaging around $600 to $900 per ton. Aluminum, while lightweight and corrosion-resistant, ranges from $1,800 to $2,500 per ton. These price differences can significantly impact your budget.

Remember to factor in the specific requirements of your project. For instance, if you need durability and strength, steel may be worth the higher initial investment. On the other hand, if weight is a key concern, aluminum might be the better option despite its cost. Each type of metal has unique properties that can affect long-term expenses.

Tips: Always source your materials from reputable suppliers to avoid hidden costs. Consider additional expenses like transportation and processing. Comparing prices and properties upfront can save you money later. Ultimately, your choice should align not just with your budget but also with your project's demands. Be prepared to adjust your plans based on metal availability and market prices, as fluctuations can impact your overall costs.

Cost Analysis: Comparing Price Per Ton for Various Metal Bar Types

This chart illustrates the cost per ton for different types of metal bars, assisting you in making an informed decision for your project.

Sustainability and Recycling: Eco-Friendly Options for Metal Bars

Choosing the right metal bar involves understanding its impact on the environment. Eco-friendly options are becoming popular in various industries.

Steel, for example, can be recycled indefinitely without loss of quality. According to the World Steel Association, about 85% of all steel is recycled globally. This high recycling rate reflects a strong commitment to sustainability.

Another option is aluminum, which is lightweight and recyclable. The Aluminum Association reports that recycling aluminum saves 90% of the energy required to produce new aluminum. However, the energy-intensive production of primary aluminum raises concerns. Balancing energy use and recycling is crucial. Opting for locally sourced metal bars can also reduce carbon footprints.

Sourcing materials sustainably is still a challenge. While metal recycling rates are high, not all facilities operate at optimal efficiency. Continuous improvement is needed to enhance operations. Consumers now demand transparency regarding sourcing and recycling processes. They want assurance that their choices contribute positively to the environment. This shift is slowly changing industry practices, but there is more to be done for complete sustainability.

Related Posts

-

How to Select the Best Bar Steel for Your Construction Needs

-

Why Steel Bar is Essential for Construction and Its Impact on Structural Integrity

-

Top Benefits of Using Stainless Steel Bars in Construction and Manufacturing

-

How to Find Reliable Steel Supply Sources for Your Projects

-

The Future of Hot Rolled Bars in Construction and Manufacturing Industries

-

Understanding the Essential Role of Steel in Modern Construction and Infrastructure