How to Choose the Right Stainless Steel Grades for Your Project?

Choosing the right stainless steel grades for a project can be challenging. The decision impacts durability, cost, and performance. According to a recent report by Smith Industrial Research, nearly 50% of engineering failures are linked to improper material selection. Understanding stainless steel grades is crucial for success.

Renowned expert Dr. Emily Chen states, “Selecting the correct stainless steel grades can prevent costly mistakes.” Her insights emphasize the importance of informed choices. Each grade offers unique properties, including corrosion resistance and strength. For example, 304 stainless steel is versatile, while 316 provides superior resistance to harsh environments.

However, many projects still choose materials without thorough analysis. This oversight can lead to increased maintenance and even project delays. It is essential to reflect on past decisions to improve future outcomes. Investing in the right stainless steel grades not only enhances project longevity but also boosts efficiency.

Understanding Stainless Steel Grades and Their Characteristics

Stainless steel comes in various grades, each having unique properties. Understanding these differences is essential for successful projects. The most common grades include 304 and 316. Grade 304 offers good corrosion resistance and is often used in kitchen appliances. It is versatile, but it may lack strength in certain harsh environments.

Conversely, grade 316 contains molybdenum, enhancing its resistance to chloride corrosion. This makes it ideal for marine applications. Yet, despite its strengths, 316 is typically more expensive. Cost may not always equal better performance for every project, introducing room for errors in judgment.

When choosing a grade, consider the environment and intended use. Some might overlook the significance of weldability and formability. If heavy fabrication is needed, a more ductile grade might suit better. A mistake in this decision can lead to project delays or failure. Each choice carries weight and requires thoughtful consideration.

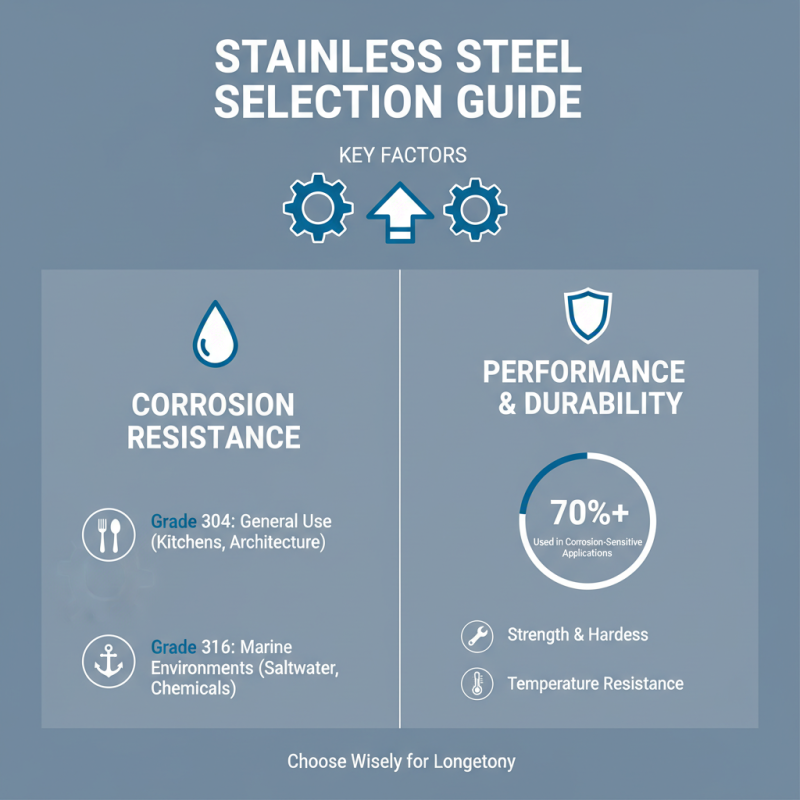

Factors to Consider When Choosing Stainless Steel for Your Project

Choosing the right stainless steel grade for your project can be challenging. There are several factors to consider that significantly impact performance and durability. Corrosion resistance is a major factor. For instance, certain grades like 304 are suitable for general use, while 316 excels in marine environments. According to industry reports, more than 70% of stainless steel is used in corrosion-sensitive applications.

Another crucial element is mechanical properties. The tensile strength and hardness of the steel can determine its suitability for specific tasks. For buildings and structures, grades with higher yield strengths like 430 can be beneficial. However, remember that selecting a harder grade may also lead to machining difficulties.

Tips: Always assess the environment. Hot or acidic conditions demand different materials. 316 may seem ideal, but its cost can be a hurdle. Evaluate your budget while prioritizing safety and longevity. Balancing cost and quality is not always easy but essential. Aim for a selection that won’t necessitate replacements soon. Ultimately, investing time in understanding these factors pays off in project outcomes.

Applications of Different Stainless Steel Grades in Various Industries

Selecting the right stainless steel grade is crucial for any project. Each grade has unique properties suitable for specific applications. For example, 304 stainless steel is commonly used in food processing. Its corrosion resistance is ideal for kitchen equipment. This grade is safe and easy to clean, making it popular among restaurants.

Another notable grade is 316 stainless steel. This grade contains molybdenum, enhancing its resistance to saltwater and harsh chemicals. It is widely used in marine applications. However, it's also more expensive than 304. This decision could lead to budget concerns. Understanding where to allocate resources is essential.

The use of stainless steel in the automotive industry is another example. Grades such as 430 provide good corrosion resistance. Yet, their magnetic properties can be a downside in some electric parts. Knowing the specific requirements of each application helps avoid these pitfalls. Each choice has its own set of challenges and considerations.

How to Choose the Right Stainless Steel Grades for Your Project? - Applications of Different Stainless Steel Grades in Various Industries

| Stainless Steel Grade | Common Applications | Corrosion Resistance | Strength |

|---|---|---|---|

| 304 | Food processing, kitchen equipment, chemical storage | Good | Moderate |

| 316 | Marine environments, pharmaceutical equipment, pollution control | Excellent | Moderate |

| 430 | Automotive trim, appliance components, kitchenware | Fair | High |

| Duplex 2205 | Oil and gas, chemical processing, desalination plants | Very Good | Higher than 304 and 316 |

| 15-5 PH | Aerospace, nuclear reactors, food processing | Good | High |

Comparing Corrosion Resistance and Durability of Stainless Steel Types

When choosing stainless steel grades for your project, corrosion resistance is key. Some types offer better protection than others. For example, austenitic stainless steels, like 304 and 316, resist rust well. They contain nickel and chromium, enhancing durability. Yet, they are not invincible. In harsh environments, even these grades can corrode over time.

A significant factor is the environment. Chlorides can accelerate corrosion. Thus, 316 is often preferred in marine applications due to its superior resistance. Ferritic stainless steels, while more magnetic, are less resistant to pitting. Think about where your project will be. Will it be exposed to moisture or chemicals?

However, the choice isn’t always clear. Cost and availability can impact your decision. Some may lean towards cheaper grades and regret it later. It’s crucial to assess long-term needs. Reviewing failure cases in similar projects reveals important lessons. Each project is unique. Evaluating corrosion resistance properly can prevent future setbacks.

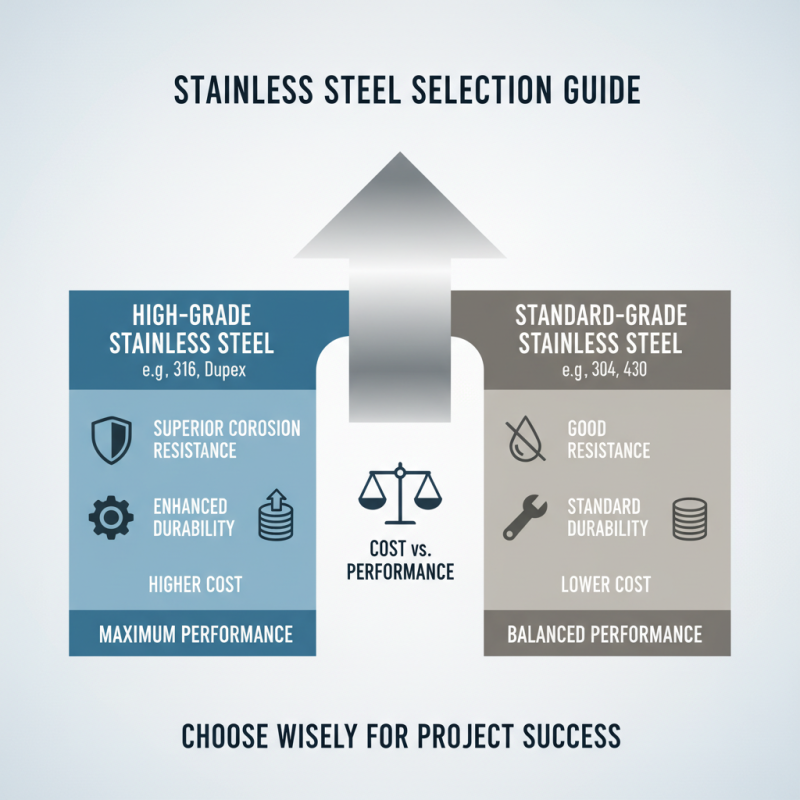

Evaluating Cost vs. Performance in Selecting Stainless Steel Grades

Choosing the right stainless steel grade is crucial for any project. The balance between cost and performance often dictates the decision. Higher-grade stainless steel can provide excellent corrosion resistance and durability. However, this comes with a higher price tag.

For instance, 316 stainless steel offers better resistance to chlorides than 304. This makes it ideal for marine environments. But, if your project is on a tight budget, 304 might suffice. It's essential to analyze the specific requirements. Will the material be exposed to harsh conditions? Consider the long-term costs versus the immediate savings.

Think about the project’s lifespan. Cheaper grades may lead to frequent replacements. That’s a hidden cost many overlook. Performance should not be sacrificed for savings. Test and evaluate your options. Each project is unique. Do not assume one grade fits all. Reflect on what will work best for your needs.

Related Posts

-

How to Choose the Right Stainless Steel Grades for Your Project

-

Understanding Different Stainless Steel Grades and Their Applications

-

Exploring the Unique Properties and Applications of Stainless Steel Wire in Modern Manufacturing

-

Exploring the Future of Carbon Steel: Insights from the 138th Canton Fair 2025 in China

-

The Versatile Applications of Stainless Steel Wire Rod in Modern Industries

-

2025 Top Cold Drawn Steel Bar Applications and Benefits for Industry