How to Choose the Right Stainless Steel Grades for Your Project

Choosing the right stainless steel grades for your project is a critical step that can significantly influence both performance and longevity. With hundreds of stainless steel grades available, it can be a daunting task to identify which one best suits your specific application requirements. According to a recent industry report by the International Stainless Steel Forum (ISSF), the global stainless steel production reached approximately 50 million metric tons in 2022, emphasizing the material's growing relevance across various sectors including construction, automotive, and food processing.

As John Smith, a noted expert in metallurgical engineering, states, "Selecting the appropriate stainless steel grade is not just about corrosion resistance; it involves understanding the environmental conditions and mechanical demands the material will face." With the right grade, projects can achieve optimal durability and efficiency, while wrong choices may lead to increased maintenance costs and early material failure. In this landscape of diverse options, a strategic approach to selecting stainless steel grades becomes essential for ensuring the success of engineering and manufacturing endeavors.

Understanding Stainless Steel Grades: An Overview

Stainless steel is renowned for its durability and resistance to corrosion, making it a popular choice for various applications. Understanding the different grades of stainless steel is crucial for selecting the right material for your project. The primary categorization includes austenitic, ferritic, and martensitic stainless steels. Austenitic grades, characterized by their high nickel content, offer excellent corrosion resistance and formability, often used in kitchen equipment and chemical processing. On the other hand, ferritic grades, which contain chromium as the primary alloying element, provide moderate corrosion resistance and are typically found in automotive applications and architectural features.

Each grade of stainless steel comes with specific properties suited to various environments and performance requirements. For instance, martensitic stainless steels are known for their high strength and hardness, making them suitable for applications that require wear resistance, such as cutlery and industrial blades. Understanding the composition and properties of these grades helps engineers and designers make informed decisions based on the environment, mechanical stress, and exposure to chemicals in their projects. This knowledge is essential to ensure the longevity and functionality of stainless steel components, leading to successful outcomes in construction, manufacturing, and beyond.

Key Properties of Stainless Steel: Corrosion Resistance and Strength

When selecting the right stainless steel grade for a project, understanding key properties such as corrosion resistance and strength is crucial.

Stainless steel is renowned for its ability to resist rust and corrosion, attributed primarily to its chromium content.

This element forms a passive layer of chromium oxide on the surface, which not only protects the underlying metal but also self-heals if damaged.

The level of corrosion resistance varies among the different grades of stainless steel, making it essential to choose a grade that suits the specific environmental conditions the material will face, such as exposure to moisture, chemicals, or extreme temperatures.

In addition to corrosion resistance, strength is another critical factor in the selection process.

Stainless steel is available in various grades that offer different tensile strengths and yield strengths, which determine how much load the material can bear before deforming or breaking.

For applications requiring high strength, grades such as Martensitic stainless steels offer enhanced hardness and resistance to wear.

Conversely, for projects where ductility and formability are more critical, Austenitic stainless steels may be the better choice.

By assessing the specific requirements of your project and balancing these properties, you can select the most appropriate stainless steel grade that delivers both durability and performance.

Common Stainless Steel Grades and Their Applications in Various Industries

Stainless steel is a versatile material with various grades designed to meet specific requirements across different industries. Among the most common grades, 304 is widely used in food processing and kitchen equipment due to its excellent corrosion resistance and ease of cleaning. This makes it ideal for environments where hygiene is paramount. Similarly, 316 stainless steel is preferred in marine applications and chemical processing due to its enhanced corrosion resistance, particularly against chlorides, which can cause pitting and rust.

In the construction and architectural sectors, grade 430 is often utilized for its aesthetic properties and good corrosion resistance in less severe environments. This grade is commonly found in decorative applications and automotive trim. For high-strength applications, such as in the aerospace and automotive industries, grades like 17-4 PH are essential. This grade is appreciated for its mechanical properties and is applicable in situations requiring both strength and corrosion resistance. Understanding the specific characteristics and applications of these stainless steel grades is crucial for making informed decisions in project planning and material selection.

Common Stainless Steel Grades and Their Applications

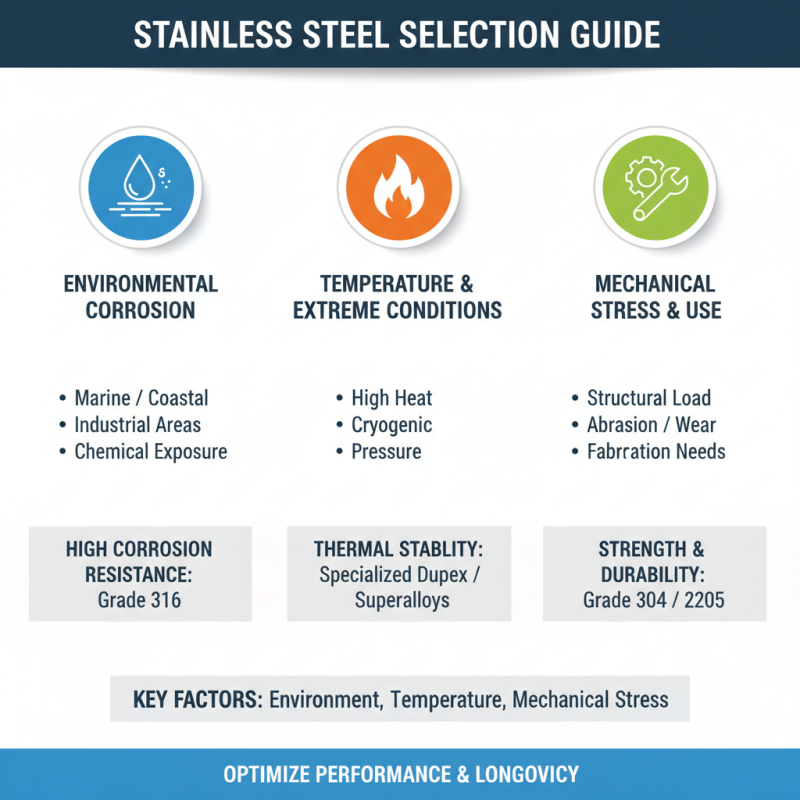

Factors to Consider When Selecting Stainless Steel Grades for Projects

When selecting the appropriate stainless steel grades for your project, it is crucial to consider several key factors that can influence both the performance and longevity of the material. One significant aspect is the environment in which the stainless steel will be used. For instance, if the project is exposed to high levels of corrosion, such as in marine environments, opting for a higher grade like 316 stainless steel can provide better resistance compared to other grades. Similarly, applications involving high temperatures or extreme conditions may require specialized grades that can withstand such stresses without losing their structural integrity.

Another important consideration is the mechanical properties required for your project, including strength, hardness, and ductility. Different stainless steel grades offer varying levels of these properties, so understanding the load and stress your project will endure can help in selecting the right grade. For example, if the project requires high strength combined with good formability, grades like 304 or 301 might be ideal choices.

Tips: Always consult with a materials expert or perform a risk assessment to determine the best grade for your specific needs. Conduct a thorough analysis of the chemical composition, corrosion resistance, and temperature factors relevant to your environment. Additionally, consider how fabrication processes, such as welding or machining, may be affected by the stainless steel grade you choose, as this can impact the overall integrity of the project.

Industry Standards and Certifications for Stainless Steel Grades Selection

When selecting the right stainless steel grades for your project, understanding industry standards and certifications is crucial. Different applications require varying levels of corrosion resistance, strength, and durability, making it essential to familiarize yourself with the specifications relevant to your project. For instance, standards set by organizations like ASTM, ISO, and ASME provide a foundation for evaluating the mechanical properties and corrosion resistance of different stainless steel grades. Always check the certification details accompanying the materials to ensure they meet the requirements for your specific application.

Tips: One effective strategy is to make a checklist of the project requirements, including environmental conditions, mechanical stress, and aesthetic considerations. This checklist will guide you in selecting the appropriate grade that aligns with the industry standards. Additionally, collaborating with suppliers who can provide comprehensive documentation and certifications can help clarify which stainless steel grades conform to industry norms.

It's also beneficial to stay informed about updates in standards and certifications. Materials science is continually evolving, and new grades or treatments may emerge that offer improved performance. Subscribe to industry publications or attend workshops to keep your knowledge current. By prioritizing these standards, you’ll enhance the success and longevity of your projects.

How to Choose the Right Stainless Steel Grades for Your Project - Industry Standards and Certifications for Stainless Steel Grades Selection

| Grade | Corrosion Resistance | Tensile Strength (MPa) | Common Applications | Industry Standards |

|---|---|---|---|---|

| 304 | Good | 520 | Food processing, kitchen equipment | ASTM A240 |

| 316 | Excellent | 580 | Marine applications, medical devices | ASTM A240 |

| 430 | Moderate | 480 | Decorative applications, automotive parts | ASTM A240 |

| Duplex 2205 | Very Good | 700 | Oil and gas, chemical processing | ASTM A240 |

| 17-4 PH | Good | 930 | Aerospace, mechanical components | ASTM A564 |

Related Posts

-

Understanding Cold Drawn Steel Bar: Characteristics, Applications, and Benefits

-

Exploring the Versatile Applications of Steel Wire Rod in Modern Construction and Manufacturing

-

What is Carbon Steel and How is it Different from Other Steels

-

Top 5 Reasons Why Wire Steel is Essential in Construction and Manufacturing

-

2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations

-

2025 Top Cold Drawn Steel Bar Applications and Benefits for Industry