What is Carbon Steel and How is it Different from Other Steels

Carbon steel is a fundamental material in the world of metallurgy, distinguished by its unique characteristics that set it apart from other types of steel. According to Dr. Emily Carter, a leading expert in materials science, "Carbon steel offers a versatile balance of strength and flexibility, making it an essential choice for a variety of industrial applications." This versatility arises from the varying carbon content in the steel, which influences its properties and performance.

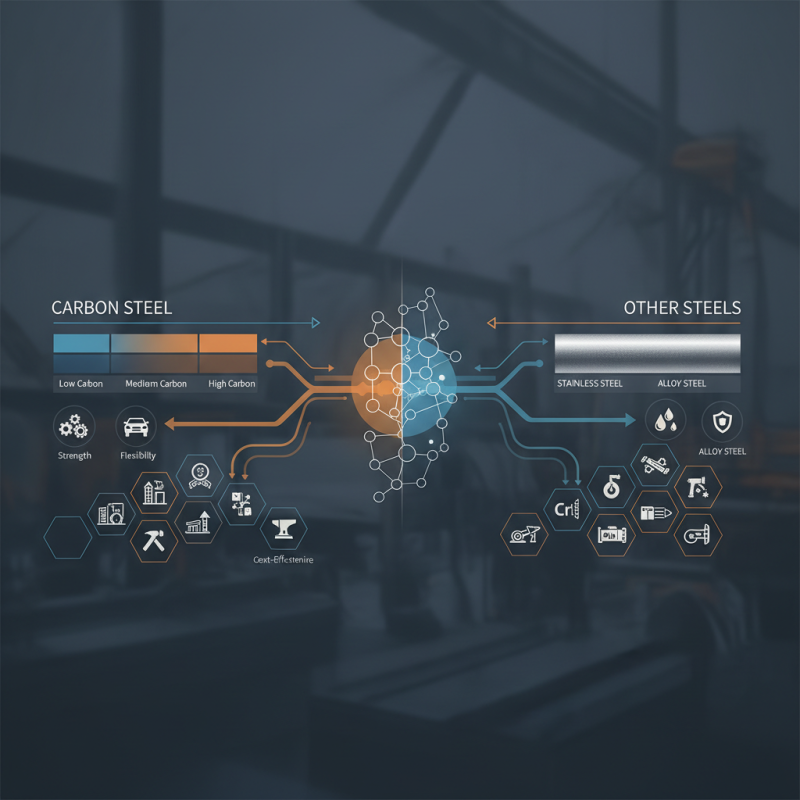

Understanding the differences between carbon steel and other steel types, such as stainless steel or alloy steel, is crucial for engineers and manufacturers alike. Carbon steel can be divided into different categories based on its carbon levels, ranging from low to high carbon, each serving distinct purposes in construction, automotive, and machinery industries. The unique blend of properties found in carbon steel, including durability and cost-effectiveness, makes it a preferred material for many professionals.

As we delve deeper into the realm of carbon steel, we will explore its composition, properties, and applications, highlighting why it remains a favorite among industries worldwide. The ongoing advancements in carbon steel technology continue to enhance its effectiveness and adaptability, ensuring its relevance in modern engineering and manufacturing environments.

What is Carbon Steel?

Carbon steel is a type of steel that primarily consists of iron and carbon, with carbon content typically ranging from 0.05% to 2.0% by weight. This composition defines its mechanical properties, making carbon steel a versatile material used in a wide array of applications. The amount of carbon present influences both hardness and ductility, allowing for different grades of carbon steel, such as low, medium, and high carbon steel, each suited to specific uses. For instance, low carbon steel is softer and more malleable, suitable for forming applications, while high carbon steel is harder and more suited for cutting tools and high-strength applications.

The production of carbon steel does not involve significant alloying elements, which distinguishes it from other types of steel, such as alloy steel or stainless steel. Alloy steels contain additional elements that enhance specific properties, like corrosion resistance or toughness. While carbon steel is more susceptible to rust and corrosion compared to stainless steel, its ease of fabrication and cost-effectiveness make it a popular choice in construction, automotive, and manufacturing industries. Understanding the characteristics of carbon steel is crucial for selecting the appropriate materials for various engineering challenges, contributing to optimal performance and longevity in finished products.

What is Carbon Steel and How is it Different from Other Steels

| Property | Carbon Steel | Alloy Steel | Stainless Steel |

|---|---|---|---|

| Carbon Content | 0.05% - 2.0% | Up to 1.5% | Up to 0.15% |

| Key Characteristics | Good strength, ductility, and low cost | Improved strength and hardness | Corrosion resistance and high strength |

| Common Uses | Construction, automotive, tools | Machinery, aerospace, automotive | Kitchen appliances, medical instruments |

| Heat Treatment | Quenched and tempered for hardness | Various hardening processes available | Not typically hardened, may need annealing |

| Cost | Economically priced | Moderate cost | Higher cost |

Chemical Composition of Carbon Steel

Carbon steel is an alloy primarily composed of iron and carbon, with carbon content varying between 0.02% to 2.1% by weight. This composition significantly influences its properties and applications. Low carbon steels, containing up to 0.3% carbon, offer good ductility and weldability, making them ideal for structural applications. As the carbon content increases, the steel's hardness and strength improve. Medium carbon steel, with carbon content between 0.3% and 0.6%, strikes a balance, offering enhanced strength while maintaining a degree of ductility. High carbon steels, which contain 0.6% to 2.1% carbon, are used in applications requiring high wear resistance, such as cutting tools and springs.

The chemical composition of carbon steel significantly distinguishes it from other types of steel, such as alloy steels, which include additional elements like nickel or chromium to enhance specific properties. According to a report from the World Steel Association, carbon steel accounts for approximately 90% of global steel production, underscoring its pervasive use across various industries. Its widespread application can be attributed to the fact that, despite its inherent limitations in corrosion resistance and toughness compared to alloy steels, its simple chemical makeup allows for cost-effective production and versatility, catering to a vast array of industrial needs.

This chart compares the carbon content in different types of steel, highlighting how carbon steel differs from alloy steel, stainless steel, and tool steel.

Types of Carbon Steel and Their Properties

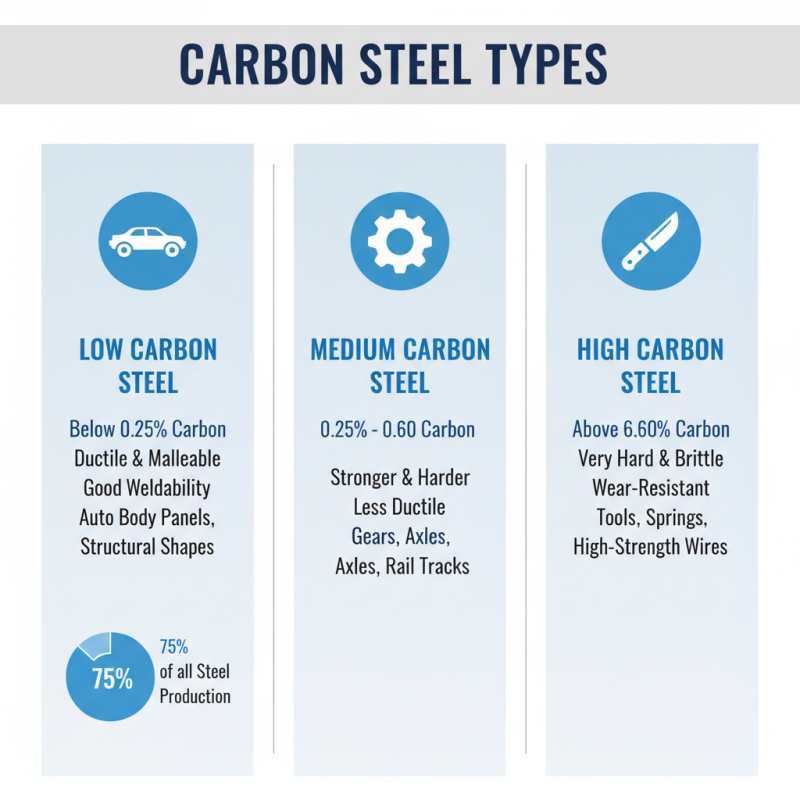

Carbon steel is categorized into three primary types based on the carbon content: low carbon steel, medium carbon steel, and high carbon steel, each possessing distinctive properties that make them suitable for various applications. Low carbon steel, with a carbon content typically below 0.25%, is known for its excellent ductility and malleability. This type generally exhibits good weldability, which makes it ideal for manufacturing products like automobile body panels and structural shapes. According to a report from the World Steel Association, low carbon steels account for approximately 75% of total steel production, emphasizing their significance in the industry.

Medium carbon steel, containing approximately 0.25% to 0.60% carbon, offers a balanced mix of strength and ductility. The increased carbon content enhances the hardness and strength of the material, making it suitable for components that require higher wear resistance, such as axles and gears. The mechanical properties of medium carbon steel can also be improved through heat treatment, making it an appealing choice for various manufacturing applications.

High carbon steel, which typically contains over 0.60% carbon, is known for its exceptional hardness and strength, but has reduced ductility. This type is often used in products that require superior strength and wear resistance, such as cutting tools and springs. A recent report by the American Iron and Steel Institute highlights that high carbon steels, despite their lower market share, play a crucial role in specialized industries due to their unique performance characteristics. Understanding the intricacies of these carbon steel types can help manufacturers and engineers select the appropriate material for their specific needs.

Comparison of Carbon Steel with Alloy and Stainless Steels

Carbon steel, alloy steel, and stainless steel are three primary categories of steel, each offering distinct characteristics suited for different applications.

Carbon steel is primarily composed of iron and carbon, with varying carbon content influencing its strength, ductility, and hardness. It is prized for its robustness and cost-effectiveness, making it widely used in construction and manufacturing.

However, it is prone to rust and corrosion without protective coatings.

In contrast, alloy steel incorporates additional elements such as nickel, chromium, or molybdenum, enhancing its mechanical properties and resistance to wear and fatigue.

This makes alloy steel ideal for applications requiring enhanced strength and toughness, such as in tools or heavy machinery.

On the other hand, stainless steel contains a minimum of 10.5% chromium, which provides exceptional resistance to corrosion and oxidation.

As a result, it is widely used in environments exposed to moisture and chemicals, such as in kitchenware and medical instruments.

Each type of steel has specific advantages, making them suitable for various engineering and industrial needs.

Applications of Carbon Steel in Various Industries

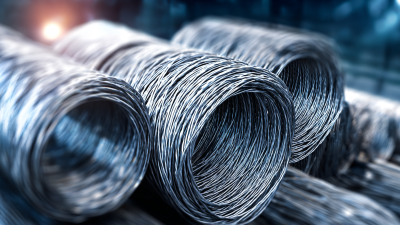

Carbon steel is a versatile material widely used across various industries due to its unique properties and cost-effectiveness. In the construction sector, carbon steel is employed for structural components such as beams and columns, thanks to its high tensile strength and durability. This makes it a preferred choice for constructing buildings, bridges, and other infrastructure projects where reliable load-bearing capacity is essential.

In the manufacturing realm, carbon steel finds applications in producing machinery parts, tools, and automotive components. Its ability to be heat-treated enhances its hardness and wear resistance, making it ideal for parts that endure significant stress and friction. Furthermore, the energy sector utilizes carbon steel in pipelines and storage tanks due to its robustness and resistance to corrosion, ensuring the safe transport and containment of gases and liquids. These varied applications demonstrate carbon steel's critical role in supporting diverse industrial needs, contributing to advancements and efficiencies across multiple fields.

Related Posts

-

Exploring the Future of Carbon Steel: Insights from the 138th Canton Fair 2025 in China

-

Steel Grades Innovations Showcased at 2025 China 138th Import and Export Fair with Industry Data Insights

-

How to Select the Best Bar Steel for Your Construction Needs

-

2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations

-

2025 Top 5 Wire Steel Innovations Transforming the Industry

-

Top 5 Applications of Wire Rods in Modern Manufacturing You Didn't Know About