The Best Types of Steel Bars for Construction and Their Benefits

In the realm of construction, selecting the right materials is crucial for ensuring structural integrity and longevity. Among various options, steel bars, particularly "i steel bar", stand out due to their exceptional strength and versatility. According to a recent report by the American Institute of Steel Construction, the demand for steel bars in the construction industry is expected to grow by 3.5% annually over the next five years, driven largely by increasing infrastructure investments and urbanization. This highlights the significance of understanding the best types of steel bars available.

Renowned construction materials expert Dr. Robert Jenkins emphasizes, “The resilience and adaptability of i steel bars make them an indispensable component in modern engineering projects.” His insights shed light on the various benefits these bars provide, including their high tensile strength, resistance to deformation, and cost-effectiveness. As construction projects become more ambitious, the choice of materials plays a pivotal role in achieving desired outcomes. By exploring the various types and advantages of i steel bars, stakeholders can make informed decisions that enhance the safety and efficiency of their structures.

The Importance of Steel Bars in Modern Construction Practices

Steel bars play a crucial role in modern construction practices, serving as the backbone of structural integrity and durability in buildings and infrastructure. These bars, commonly made of carbon steel or alloy steel, are used to reinforce concrete and ensure it can withstand various stresses. Their high tensile strength allows structures to bear heavy loads, resist bending, and maintain stability over time, making them indispensable in high-rise buildings, bridges, and other critical infrastructure projects.

The versatility of steel bars also enhances their importance in construction. They can be produced in various grades, sizes, and shapes to fit specific engineering requirements, which facilitates their use in diverse applications. Additionally, advancements in steel manufacturing technology have improved the quality and performance of these bars, allowing for greater adaptability to different environments, climates, and load conditions. As modern construction continues to evolve, the use of steel bars remains a foundational element, ensuring that structures are not only built to last but also meet the rigorous demands of safety and efficiency in today’s architectural landscape.

Common Types of Steel Bars used in Construction: A Comprehensive Overview

When it comes to construction, steel bars play a vital role in providing the structural integrity that buildings and infrastructure require. Among the various types, rebar, or reinforcing bar, stands out as the most commonly used steel bar. Typically made from carbon steel, rebar is designed to withstand tensile stress and is often placed in concrete to enhance its strength. Its ribbed surface ensures a strong bond with the concrete, reducing the likelihood of structural failure and increasing the durability of the construction.

Another significant type of steel bar used in construction is the steel flat bar, known for its versatility and ease of use. These bars are ideal for various applications, including frames, brackets, and supports. Their flat surface allows for easy welding and fabrication, making them a favorite for builders seeking flexibility in design while ensuring stability.

In addition, steel round bars are utilized for applications requiring high strength, such as in components subjected to high loads. Their cylindrical shape offers exceptional tensile strength, making them perfect for reinforcing structures where resilience is paramount.

Overall, the choice of steel bars in construction determines the building's overall quality and longevity. Understanding the characteristics and applications of these common types enables contractors and engineers to make informed decisions, ultimately contributing to safer, more reliable construction practices.

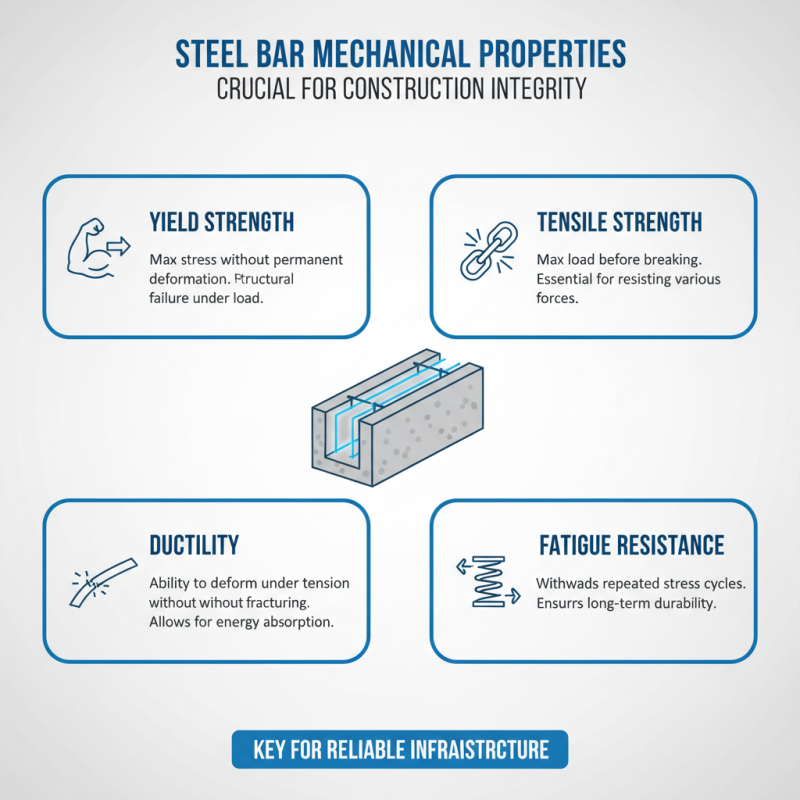

Mechanical Properties of Steel Bars and Their Impact on Structural Integrity

The mechanical properties of steel bars play a crucial role in determining their suitability for construction applications. Key properties such as yield strength, tensile strength, ductility, and fatigue resistance are fundamental in maintaining the structural integrity of buildings and infrastructure. Yield strength, which indicates the maximum stress that a material can withstand without permanent deformation, is particularly significant; it ensures that the structure can support loads without risking failure. Similarly, tensile strength refers to the maximum load the steel can handle before breaking, which is essential for structures subjected to various forces.

Ductility, the ability of steel to deform under stress without fracturing, contributes significantly to safety in construction. Ductile steel bars can absorb energy from impacts, providing a warning before failure occurs. This characteristic is especially important in seismic-prone areas where buildings must withstand dynamic loads. Furthermore, good fatigue resistance allows steel to endure repeated loading cycles without significant degradation, which is critical for long-term durability. Together, these mechanical properties ensure that steel bars can meet the demanding requirements of modern construction, leading to safer, more resilient structures.

Comparative Benefits of Different Grades of Steel Bars in Construction

When it comes to construction, selecting the appropriate grade of steel bars is crucial not only for structural integrity but also for cost-effectiveness. Steel bars, categorized primarily into different grades such as TMT (Thermo-Mechanically Treated) and CTD (Cold Twisted Deformed), offer varying tensile strengths and ductility. For instance, according to industry data from the American Concrete Institute, TMT bars typically feature a tensile strength of 500 MPa, making them suitable for high-stress applications. In contrast, CTD bars, with their lower strength grades, can be ideal for less demanding structures and can save on initial material costs.

One of the notable advantages of using higher grade steel bars, like TMT, is their better resistance to corrosion. A study by the International Journal of Civil Engineering and Technology suggests that structures built with TMT bars have enhanced longevity due to this resistance. Furthermore, these bars can withstand seismic activities better than their lower-grade counterparts, which is essential in regions prone to earthquakes.

Tips: When selecting steel bars for your construction project, consider the environmental conditions and expected loads. Engaging a structural engineer to analyze your specific requirements will further optimize material selection and enhance the overall safety of your construction. Additionally, investing in higher-grade bars may result in long-term savings due to decreased maintenance costs.

Emerging Trends and Innovations in Steel Bar Manufacturing for the Industry

The steel bar manufacturing industry is witnessing significant transformations, driven by advancements in technology and increasing demands for sustainable construction practices. Emerging trends such as the use of eco-friendly steel production methods, including the implementation of electric arc furnaces (EAF), are on the rise. According to a recent report by the World Steel Association, the adoption of EAF can reduce carbon emissions by up to 75% compared to traditional blast furnace methods, making it a pivotal innovation for the industry.

Furthermore, automation and smart manufacturing are reshaping the production processes of steel bars. The integration of artificial intelligence and machine learning algorithms allows for real-time monitoring and improvements in quality control. This technological leap not only enhances efficiency but also fosters greater accuracy in steel bar production, leading to a decrease in waste. A report from McKinsey states that the adoption of Industry 4.0 technologies could lead to operational cost reductions of up to 20% across the steel supply chain.

**Tips:** To maximize the benefits of modern steel bar innovations, construction professionals should stay informed about the latest manufacturing practices and consider partnerships with manufacturers that prioritize sustainability. Additionally, investing in training for the workforce on new technologies can further enhance productivity and quality assurance on-site. By embracing these trends, the construction industry can achieve both economic and environmental benefits.

The Best Types of Steel Bars for Construction and Their Benefits

This chart illustrates the advantages of various types of steel bars used in construction, showcasing their significant benefits through a scoring system. Reinforcing steel (rebar) stands out with the highest advantages score, indicating its crucial role in structural integrity.

Related Posts

-

How to Select the Right Bar Steel for Your Construction Projects

-

Top 5 Applications of Wire Rods in Modern Manufacturing You Didn't Know About

-

2025 Top 5 Wire Steel Innovations Transforming the Industry

-

What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

-

Exploring the Growth of Industrial Steel Demand at China Import and Export Fair 2025

-

Understanding the Essential Role of Steel in Modern Construction and Infrastructure