Top Benefits of Using Stainless Steel Bars in Construction and Manufacturing

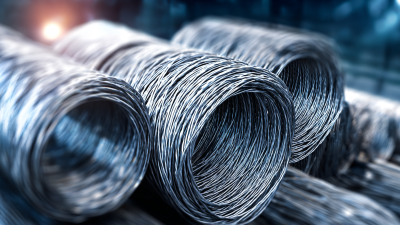

The construction and manufacturing industries have increasingly turned to stainless steel bars for their superior strength, durability, and corrosion resistance. According to a recent report by the International Stainless Steel Forum, the global demand for stainless steel products is projected to reach 50 million tons by 2025, driven by its extensive applications in various sectors. The adoption of stainless steel bars plays a crucial role in this growth, providing essential structural support and enhancing the longevity of manufactured goods.

Renowned expert Dr. Mark Liu, a leading figure in materials engineering, emphasizes the significance of stainless steel bars in modern construction. He states, "The mechanical properties of stainless steel bars not only contribute to safety and structural integrity but also optimize maintenance costs over the lifespan of a project." This underscores the economic advantages of using stainless steel bars, as they reduce the need for frequent replacements and repairs, ultimately leading to more sustainable practices in both construction and manufacturing.

In summary, integrating stainless steel bars into projects not only addresses the immediate demands for strong and reliable materials but also aligns with long-term economic and environmental goals. As industries evolve, the emphasis on high-quality materials like stainless steel bars continues to shape the future of construction and manufacturing, ensuring they remain resilient against the challenges of time and climatic conditions.

Key Properties of Stainless Steel Bars for Construction and Manufacturing

Stainless steel bars are essential materials in construction and manufacturing due to their remarkable properties, which contribute to durability and resilience. One of the key properties of stainless steel is its high corrosion resistance, which is primarily attributed to the presence of chromium that forms a passive layer over the metal. According to a report by the World Stainless Association, stainless steel has an average lifespan of 50 years or more in various environments, making it an economical choice over the long term. This longevity helps reduce the need for frequent replacement and maintenance, ultimately lowering operational costs for construction projects.

Another significant property of stainless steel bars is their mechanical strength. They exhibit high tensile strength, allowing them to bear substantial loads while maintaining structural integrity. The American Iron and Steel Institute highlights that stainless steel can achieve yield strengths exceeding 200 MPa, depending on the alloy composition and treatment processes. This strength is crucial in construction applications, especially in high-rise buildings and infrastructure projects where load-bearing capacity and safety are paramount. Additionally, stainless steel’s ability to withstand extreme temperatures and its non-combustibility further enhance its reliability in diverse manufacturing environments, making it a top choice for engineers and architects alike.

Top Benefits of Using Stainless Steel Bars in Construction and Manufacturing

This chart illustrates the key properties of stainless steel bars used in construction and manufacturing, highlighting their advantages based on specific metrics.

Corrosion Resistance: Why It Matters in Construction Applications

Corrosion resistance is a critical factor in construction applications, and stainless steel bars offer exceptional durability in this regard. Unlike conventional steel, which is prone to rust and degradation when exposed to moisture and harsh environments, stainless steel contains chromium that forms a protective layer. This layer acts as a barrier against corrosion, significantly extending the lifespan of structural elements.

In construction projects, where materials are often subjected to various environmental stressors, the use of stainless steel bars ensures unparalleled performance and reliability.

Moreover, the resistance to corrosion enhances the overall safety of constructions. Structures that deteriorate due to rust can pose serious risks, potentially leading to catastrophic failures. By opting for stainless steel bars, builders can minimize maintenance costs and reduce the likelihood of repairs, ensuring that projects remain secure over time.

This longevity not only preserves the integrity of the construction but also maintains aesthetic appeal, as stainless steel retains its finish and luster. In essence, the choice of stainless steel bars is not merely about strength; it embodies a commitment to quality, safety, and sustainability in the construction industry.

Strength and Durability: Performance Benefits of Stainless Steel Bars

Stainless steel bars are increasingly recognized for their exceptional strength and durability, making them a prime choice in construction and manufacturing industries. One of the most notable performance benefits of stainless steel bars is their high tensile strength, which allows them to withstand substantial loads and stresses without deforming or breaking. This characteristic is particularly important in structural applications where safety and longevity are paramount, providing peace of mind to engineers and builders alike.

Additionally, the corrosion resistance of stainless steel bars ensures they maintain their structural integrity over time, even when exposed to harsh environmental conditions.

Furthermore, stainless steel bars offer outstanding durability that surpasses many traditional materials. Their ability to resist wear and tear makes them ideal for use in demanding environments, including factories and construction sites where tools and structural elements face constant friction and impact. This durability translates into lower maintenance costs and reduced frequency of replacements, ultimately contributing to more efficient project timelines and budget management. By incorporating stainless steel bars into their designs, manufacturers and builders can achieve enhanced performance while ensuring the enduring quality of their structures and products.

Cost-Effectiveness: Long-Term Savings through Stainless Steel Usage

Stainless steel bars are increasingly becoming a preferred choice in construction and manufacturing due to their exceptional cost-effectiveness. One of the key factors contributing to long-term savings is their durability. Unlike other materials that may require frequent repairs or replacements, stainless steel offers resistance to corrosion, rust, and wear. This longevity means that projects can benefit from reduced maintenance costs over time, allowing for a more budget-friendly option in the long run.

Additionally, stainless steel bars provide a robust structural integrity that plays a critical role in the safety and reliability of various applications. Their high strength-to-weight ratio allows for lighter designs without compromising safety, translating to lower material costs and potentially reduced labor expenses during installation. These factors, combined with the possibility of recycling stainless steel, enhance its value proposition, making it an environmentally friendly choice that also aligns with economic efficiency. Investing in stainless steel bars not only contributes to immediate construction needs but also fosters sustainable practices that yield financial benefits year after year.

Top Benefits of Using Stainless Steel Bars in Construction and Manufacturing - Cost-Effectiveness: Long-Term Savings through Stainless Steel Usage

| Benefit | Description | Long-Term Savings | Expected Lifetime (Years) |

|---|---|---|---|

| Durability | Stainless steel bars are resistant to rust, corrosion, and wear. | Reduces maintenance costs over time. | 30+ |

| Low Maintenance | Requires minimal upkeep compared to other materials. | Saves on labor and repair costs. | 20+ |

| Recyclability | Made from recyclable materials, promoting sustainability. | Potential for savings on material costs when recycling. | Indefinite |

| Versatility | Can be used in various applications across industries. | Reduces the need for multiple material types. | 20+ |

| Aesthetic Appeal | Offers a modern and sleek appearance. | Can enhance property value and customer appeal. | 30+ |

Environmental Impact: Sustainability Advantages of Stainless Steel Bars

Stainless steel bars are increasingly recognized for their environmental sustainability in construction and manufacturing. One of the primary advantages of using stainless steel is its recyclability. Approximately 90% of stainless steel is recyclable, allowing it to be repurposed without losing its inherent properties. This significantly reduces the need for raw materials and cuts down on energy consumption during production. When combined with its durability, which results in longer lifespans and reduced maintenance costs, stainless steel proves to be a highly sustainable choice for various applications.

Additionally, the production of stainless steel bars utilizes advanced methods that minimize environmental impact. Modern manufacturing techniques often incorporate energy-efficient processes and environmentally-friendly practices that further diminish the carbon footprint. When selecting materials for construction, it’s essential to consider not only the immediate benefits but also the long-term sustainability of the chosen materials.

Tips: When planning a construction project, consider switching to stainless steel bars to enhance sustainability efforts. Collaborate with suppliers who prioritize eco-friendly practices and ensure you understand the lifecycle of the materials chosen. Regular assessments of material performance can help optimize resource use and contribute to greener construction practices. Moreover, consider public perception; using sustainable materials can boost your project’s reputation and appeal to eco-conscious clients.

Related Posts

-

What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

-

2025 Top 5 Wire Steel Innovations Transforming the Industry

-

Top 10 Benefits of Using Hot Rolled Bars in Construction and Manufacturing

-

Top 5 Applications of Wire Rods in Modern Manufacturing You Didn't Know About

-

The Versatile Applications of Stainless Steel Wire Rod in Modern Industries

-

The Ultimate Guide to Rolled Steel: Innovations, Applications, and Sustainability in 2023