Top 10 Benefits of Using Hot Rolled Steel Bars in Construction and Manufacturing

The use of hot rolled steel bars in construction and manufacturing has surged in popularity, attributed to their numerous advantages that enhance structural integrity and efficiency. Hot rolled steel bars are produced through a process that involves shaping steel at elevated temperatures, resulting in superior mechanical properties and a high level of versatility. This unique manufacturing technique not only allows for easier manipulation and fabrication but also yields products that meet the demanding specifications required in various applications.

One of the primary benefits of employing hot rolled steel bars is their cost-effectiveness. The production process eliminates the need for extensive post-processing, enabling manufacturers to provide a reliable and affordable material for construction projects. Additionally, hot rolled steel bars exhibit excellent strength-to-weight ratios, making them ideal for both structural and industrial applications where load-bearing capabilities are critical. With the growing emphasis on sustainability, these bars also promote eco-friendly construction practices, as they can be sourced from recycled materials and are recyclable themselves.

As we delve into the top ten benefits of utilizing hot rolled steel bars, it becomes evident that this material is not just a staple in the building industry but a crucial contributor to advancements in engineering and manufacturing processes. The inherent qualities of hot rolled steel bars make them an essential choice for any construction professional or manufacturer seeking durability, efficiency, and performance in their projects.

Advantages of Hot Rolled Steel Bars in Strengthening Structures

Hot rolled steel bars are widely recognized for their critical role in enhancing the strength and durability of structures in construction and manufacturing. One of the primary advantages of using these bars is their exceptional tensile strength, which allows them to withstand heavy loads and resist deformation under stress. This property makes hot rolled steel bars particularly suitable for high-strength applications, such as beams, columns, and reinforcing materials in concrete structures. The process of hot rolling also improves the microstructure of the steel, leading to increased toughness and reduction of brittleness, which is essential for ensuring the longevity of structures.

Furthermore, the malleability of hot rolled steel bars facilitates ease of fabrication. They can be easily shaped, cut, and welded, allowing engineers and builders to create complex structural components tailored to specific requirements. This flexibility not only streamlines the construction process but also contributes to the optimization of material usage, which can be crucial in cost-sensitive projects. Additionally, the ability to produce hot rolled steel bars in various sizes and thicknesses makes them an ideal choice for a wide range of applications, further enhancing their role in strengthening structures across multiple sectors.

Cost-Effectiveness of Hot Rolled Steel Bars in Construction Projects

Hot rolled steel bars are an excellent choice for construction projects due to their cost-effectiveness. The manufacturing process behind hot rolling allows for a more economical production of steel, as it reduces the need for additional processing and results in a diverse range of sizes and shapes at a lower cost. This affordability makes hot rolled steel bars particularly appealing for large-scale construction, where budget constraints often play a pivotal role in material selection.

Moreover, the versatility of hot rolled steel bars contributes to their cost-effectiveness in various applications, from structural support to reinforcement in concrete. Their strength characteristics are well-suited to withstand the demands of both building frameworks and manufacturing processes, reducing the likelihood of costly repairs or replacements. On top of this, hot rolled steel is readily available and can be sourced in bulk, further enhancing its cost-efficiency for developers and manufacturers looking to optimize their financial resources while maintaining high standards of quality.

Versatility of Hot Rolled Steel Bars in Various Manufacturing Applications

Hot rolled steel bars are renowned for their remarkable versatility across various manufacturing applications. Their production involves heating steel above its recrystallization temperature, allowing for a malleable form that can be easily shaped to meet diverse specifications. This adaptability makes hot rolled steel bars a staple in a multitude of industries, including construction, automotive, and machinery fabrication. For example, in construction, these bars are commonly used for reinforcing concrete, providing the essential strength to structures such as bridges, buildings, and roads while being flexible enough to suit intricate designs.

Moreover, the use of hot rolled steel bars extends beyond structural applications. In the manufacturing sector, they serve as foundational components in machinery parts, automotive frames, and heavy equipment. The inherent toughness and durability of hot rolled steel ensure that products can withstand demanding operational conditions, making them an ideal choice where resilience is required. This versatility not only helps manufacturers streamline their processes but also encourages innovation in product design and functionality. As industries continue to evolve, the importance of hot rolled steel bars in enhancing both performance and efficiency remains a key factor in production strategies.

Top 10 Benefits of Using Hot Rolled Steel Bars in Construction and Manufacturing

Improved Ductility and Workability of Hot Rolled Steel Bars

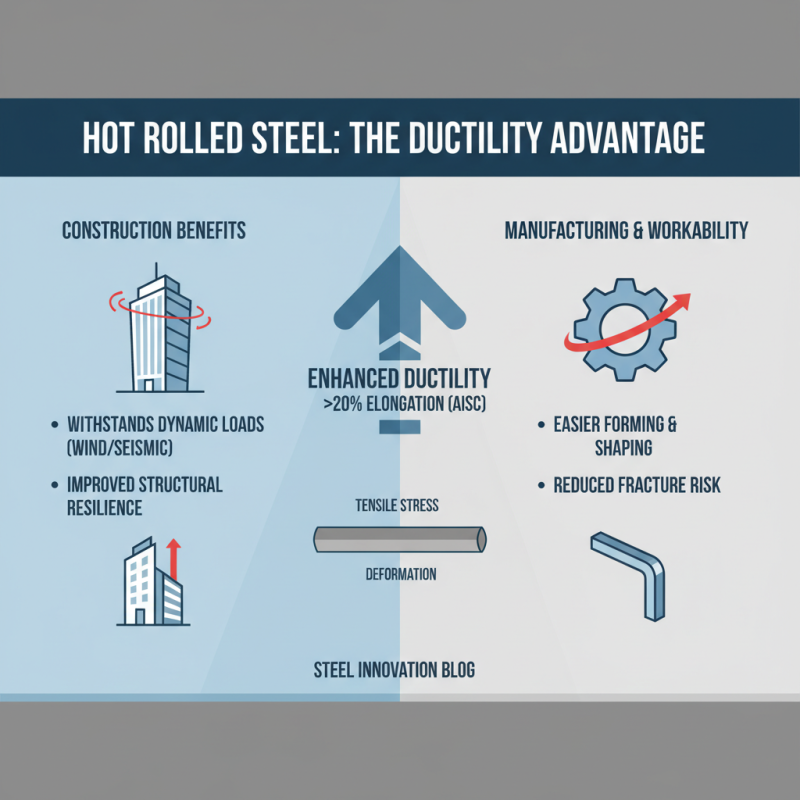

Hot rolled steel bars are increasingly favored in construction and manufacturing due to their enhanced ductility and workability, which are crucial for various applications. Ductility refers to a material's ability to deform under tensile stress, which is particularly important in construction when structures must withstand dynamic loads, such as wind or seismic activity. According to the American Institute of Steel Construction (AISC), hot rolled steel can exhibit higher elongation percentages compared to cold rolled steel, often reaching values of 20% or more, which allows for improved forming and shaping without fracturing.

The superior workability of hot rolled steel bars is another significant advantage, as this characteristic facilitates processes such as welding, cutting, and machining. A report by the World Steel Association indicates that hot rolled steel can be processed at higher temperatures, making it easier to manipulate during fabrication. This reduces the need for extensive finishing processes and speeds up construction timelines. Furthermore, the ability to easily integrate hot rolled steel into various design frameworks introduces versatility, enabling architects and engineers to innovate with structural designs while maintaining safety and integrity. The combination of ductility and workability underscores the importance of hot rolled steel bars in meeting the dynamic needs of modern construction and manufacturing industries.

Enhanced Resistance to Environmental Factors with Hot Rolled Steel Bars

Hot rolled steel bars have gained significant popularity in the construction and manufacturing sectors due to their remarkable resistance to environmental factors. Unlike cold rolled steel, hot rolled steel is processed at elevated temperatures, which not only enhances its mechanical properties but also increases its durability against rust, corrosion, and other environmental challenges. This enhanced resistance is crucial, especially for structures exposed to harsh weather conditions, as it ensures the longevity and reliability of construction projects.

Moreover, the properties of hot rolled steel bars allow for better performance under varying environmental conditions. The material can withstand fluctuations in temperature and humidity, making it an excellent choice for applications both indoors and outdoors. The thermal stability of hot rolled steel reduces the risk of warping or cracking, ensuring that structural integrity remains intact over time. Additionally, the surface finish of hot rolled steel bars contributes to its resistance, further simplifying maintenance and preservation efforts in construction and manufacturing settings.

Related Posts

-

How to Select the Best Bar Steel for Your Construction Needs

-

The Advantages of Using Rolled Steel in Modern Construction and Design

-

Understanding Hot Rolled Steel: Innovations, Processes, and Applications in Modern Industry

-

What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

-

The Best Types of Steel Bars for Construction and Their Benefits

-

Top 10 Benefits of Using Hot Rolled Bars in Construction and Manufacturing