Top 10 Benefits of Using Hot Rolled Bars in Construction and Manufacturing

In the realm of construction and manufacturing, the choice of materials plays a pivotal role in determining the efficiency, durability, and overall success of a project. One such material that has gained significant traction in various applications is hot rolled bars. These versatile products offer a combination of strength, malleability, and cost-effectiveness that make them ideal for a wide range of structural and aesthetic applications. The process of hot rolling enhances the material’s properties, resulting in bars that are easier to work with while maintaining robust performance under stress.

As industries continue to evolve and demand higher standards of reliability and performance, hot rolled bars stand out as a preferred choice among engineers and construction professionals. Their inherent characteristics, such as improved mechanical properties and reduced fabrication time, contribute to the efficiency of manufacturing processes and the longevity of construction projects. This article delves into the top ten benefits of using hot rolled bars, highlighting why they have become a staple in modern construction and manufacturing practices. From enhanced structural integrity to economic advantages, understanding these benefits is essential for making informed material choices in any project.

Benefits of Hot Rolled Bars: Enhanced Mechanical Properties and Strength

Hot rolled bars have become a cornerstone in construction and manufacturing due to their enhanced mechanical properties and strength. A significant advantage is their ability to undergo processes such as bending and shaping without suffering from structural integrity loss. According to a report by the American Institute of Steel Construction, hot rolled steel provides nominal yield strengths ranging from 36,000 to 50,000 psi, making it suitable for a variety of applications, including beams, columns, and reinforcing bars. This high strength-to-weight ratio allows for lighter structures without compromising stability, which is crucial in modern engineering design.

Additionally, hot rolled bars exhibit superior ductility, allowing them to deform under stress without cracking. This feature is particularly beneficial in seismic zones, where buildings need to withstand dynamic loads. The Steel Construction Institute highlights that the improved toughness of hot rolled steel contributes to the resilience of structures in extreme conditions, lowering the risk of catastrophic failure. Furthermore, the manufacturing process itself enhances the mechanical properties of the steel, resulting in a fine microstructure that can withstand significant operational demands. The combination of strength and ductility not only elevates the performance metrics of constructions but also boosts the overall safety and longevity of manufactured components.

Cost-Effectiveness of Hot Rolled Bars in Large Scale Manufacturing

Hot rolled bars offer significant cost-effectiveness for large scale manufacturing, making them a preferred choice among builders and manufacturers. The production process of hot rolling allows for the efficient creation of these bars at a lower cost compared to other methods. When metal is heated and then shaped, it requires less energy, which translates into savings that can be passed on to manufacturers.

Additionally, the ability to produce hot rolled bars in large quantities means that economies of scale can be achieved, further reducing per-unit costs.

Moreover, the versatility of hot rolled bars enhances their appeal in construction and manufacturing sectors. They can be easily customized in terms of size and shape to meet specific project requirements without substantial additional costs. This adaptability minimizes waste and maximizes resource use, which is crucial for large projects where every cost-saving measure contributes to the overall budget.

Furthermore, the mechanical properties of hot rolled bars, such as improved ductility and weldability, reduce the need for expensive alterations during installation, reinforcing their role as a cost-efficient solution in large scale construction and manufacturing operations.

Hot Rolled Bars: Key to Improved Fabrication Processes and Efficiency

Hot rolled bars are increasingly recognized as essential components in the construction and manufacturing sectors. These bars are produced by heating metal above its recrystallization temperature and then rolling it into desired shapes, enhancing their malleability and structural integrity. A report from the World Steel Association highlights that hot rolled products have a lower initial cost compared to cold rolled alternatives, contributing to significant savings during fabrication. This reduced cost combined with their robust structural properties makes them a preferred choice for construction projects requiring high-strength materials.

In terms of efficiency, hot rolled bars streamline the fabrication process. Their inherent properties allow for easy shaping and welding, which not only speeds up project timelines but also minimizes waste. According to a recent study by the American Institute of Steel Construction, the use of hot rolled bars can improve fabrication efficiency by up to 20%, showcasing their impact on productivity in industrial applications. The adaptability in design and reduced processing time promote better resource utilization, leading to enhanced overall project outcomes.

**Tips:** When selecting hot rolled bars for your next project, consider the specific requirements of your application, such as load capacity and environmental conditions. Additionally, ensure proper storage and handling to maintain the quality of the bars before installation. Lastly, collaborating with experienced suppliers can provide insights into the best material choices for achieving optimal efficiency in your fabrication processes.

Top 10 Benefits of Using Hot Rolled Bars in Construction and Manufacturing

Sustainability Aspect: Energy Use and Recycling in Hot Rolled Bar Production

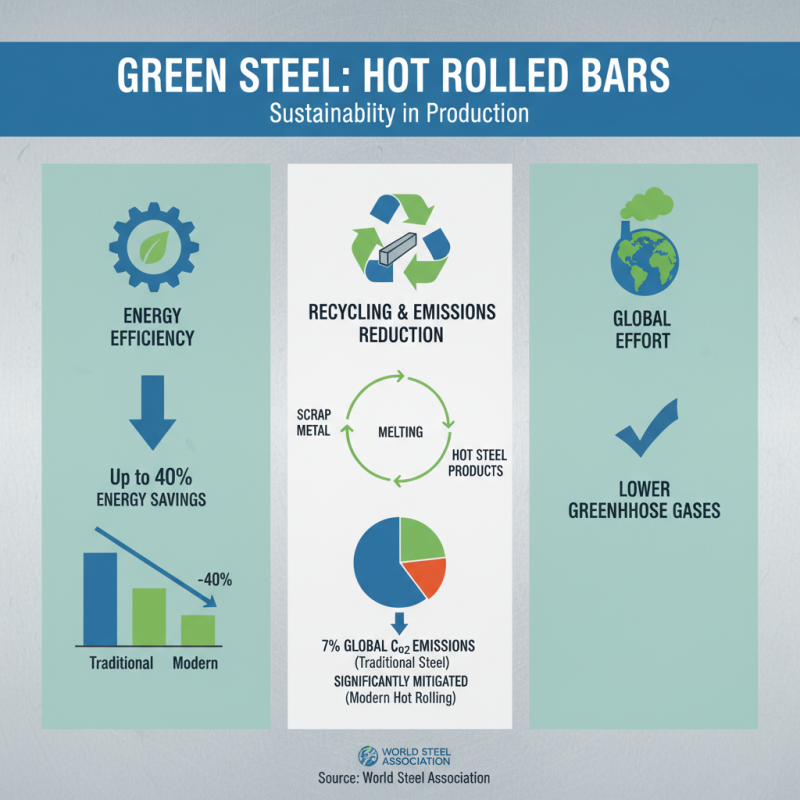

The production of hot rolled bars presents numerous sustainability benefits, particularly in terms of energy use and recycling. According to the World Steel Association, the steel industry accounts for approximately 7% of global CO2 emissions, but advancements in production technologies have significantly mitigated these figures. Modern hot rolling processes are increasingly optimized for energy efficiency, with the potential to save up to 40% of energy consumption compared to traditional methods. This reduction not only decreases energy costs but also aligns with global efforts to lower greenhouse gas emissions.

Recycling is another cornerstone of sustainability in hot rolled bar production. Steel is one of the most recycled materials in the world, with about 85% of steel from end-of-life products being recycled. The American Iron and Steel Institute reports that recycling steel cuts energy use in production by as much as 74%, as recycled scrap requires less energy to process than raw materials. Furthermore, the circular economy concept is promoted through the extensive usage of scrap metal in the production of hot rolled bars, enabling manufacturers to reduce their reliance on virgin materials while minimizing waste and environmental impact. Such practices contribute to a more sustainable construction and manufacturing sector, proving that the industry can innovate while maintaining a commitment to ecological responsibility.

Applications of Hot Rolled Bars in Structural Engineering and Infrastructure Projects

Hot rolled bars are a fundamental material in structural engineering and infrastructure projects. Their versatility and strength make them suitable for a range of applications, from the construction of bridges and buildings to various industrial frameworks. According to a recent report by the World Steel Association, hot rolled bars account for nearly 15% of all steel products used globally, highlighting their significance in the construction sector. These bars provide the necessary tensile strength required to support heavy loads, making them essential in ensuring the longevity and safety of structures.

In addition to their structural applications, hot rolled bars are also employed in manufacturing a variety of components, such as beams, columns, and reinforced concrete structures. Their ease of fabrication allows for efficient design versatility, accommodating various architectural needs. The ASTM International standards further emphasize their reliability and performance attributes, contributing to enhanced structural integrity.

**Tips:** When selecting hot rolled bars for your construction project, ensure you consider the specific load-bearing requirements and environmental factors. Additionally, opt for bars with appropriate coatings to minimize corrosion risks, especially in infrastructure projects exposed to harsh conditions. Regularly consult the latest industry standards to stay informed about advancements in material specifications and performance evaluations.

Related Posts

-

How to Select the Best Bar Steel for Your Construction Needs

-

Understanding Hot Rolled Steel: Innovations, Processes, and Applications in Modern Industry

-

What is Steel Bar Stock? A Comprehensive Guide to Types and Uses

-

Top 10 Reasons You Need Steel for Your Construction Projects

-

The Best Types of Steel Bars for Construction and Their Benefits

-

2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations