Top 10 Benefits of Using Cold Drawn Steel Bars in Construction Projects

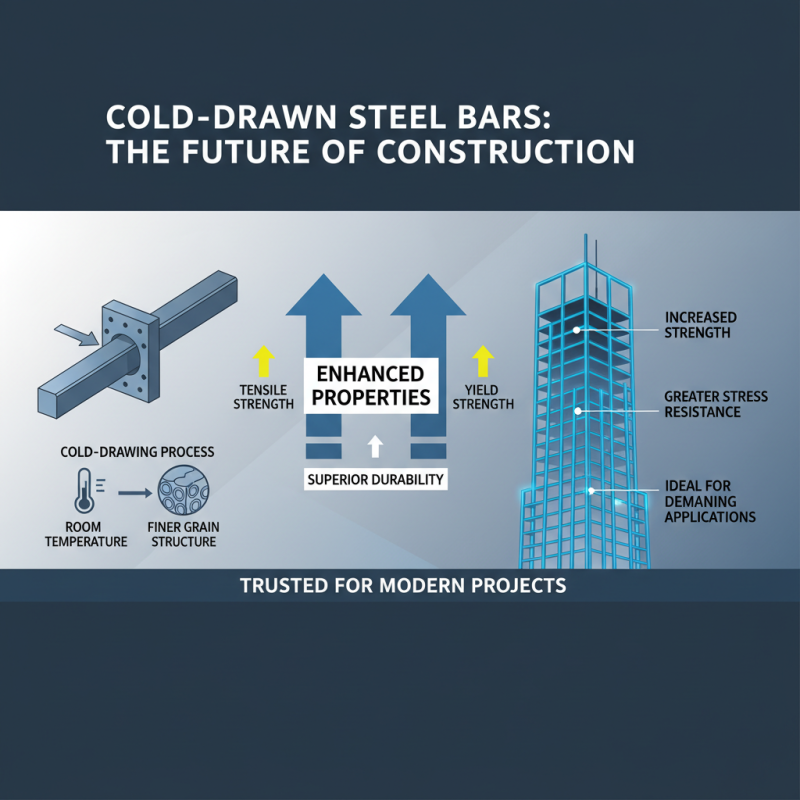

In the realm of construction, material selection plays a pivotal role in determining the durability and integrity of structures. Among the various materials available, cold drawn steel bars have gained significant recognition for their outstanding performance and versatility. Cold drawn steel bar is produced through a meticulous process that enhances its properties, making it ideal for a wide range of applications in construction projects. This method not only improves the material’s mechanical strength but also enhances its surface finish, offering benefits that cannot be overlooked.

The advantages of utilizing cold drawn steel bars in construction are manifold. Their superior tensile strength and enhanced ductility contribute to safer and more resilient structures. Furthermore, cold drawn steel bars are often more cost-effective in the long run due to their durability and resistance to wear and tear. As construction demands continue to grow, understanding the benefits of cold drawn steel bars becomes essential for architects, engineers, and construction professionals aiming to ensure quality and longevity in their projects. This article delves into the top 10 benefits of using cold drawn steel bars, highlighting why they are becoming a preferred choice in the construction industry.

Advantages of Cold Drawn Steel Bars in Structural Integrity

Cold drawn steel bars are increasingly favored in construction projects due to their significant advantages in enhancing structural integrity. One of the primary benefits of cold drawn steel bars is their superior tensile strength, which results from the cold drawing process that elongates the metal fibers. This increased strength allows for lighter structures without compromising safety, enabling engineers to design more efficient frameworks that can withstand extreme loads and environmental conditions.

In addition to their strength, cold drawn steel bars exhibit improved dimensional accuracy and surface finish compared to traditional steel bars. This precision facilitates easier handling and installation, reducing the likelihood of structural errors during construction. The smooth surface of cold drawn steel minimizes the risk of corrosion, further contributing to long-lasting structural integrity.

Overall, the use of cold drawn steel bars in construction projects not only enhances the robustness of the structures but also streamlines the construction process, making it a preferred choice for modern building applications.

Enhanced Dimensional Accuracy for Construction Applications

Cold drawn steel bars are increasingly favored in construction due to their enhanced dimensional accuracy, a crucial factor for the success of various projects. The process of cold drawing involves pulling the steel through a die at room temperature, which not only refines the grain structure of the material but also ensures that the bars achieve precise measurements. This level of precision means that builders can rely on consistent dimensions for intricate designs and applications, reducing the likelihood of errors that could compromise structural integrity and overall project timelines.

Moreover, the superior dimensional accuracy of cold drawn steel bars facilitates easier assembly and fitting during construction. When components are manufactured to exact specifications, it minimizes the need for additional machining or adjustments on-site, streamlining the construction process. This efficiency can lead to significant time savings and lower labor costs, allowing for more efficient project execution without sacrificing quality. In essence, the use of cold drawn steel bars not only enhances the reliability of construction projects but also contributes to improved cost-effectiveness and better resource management.

Improved Strength and Durability Compared to Traditional Steel

Cold drawn steel bars are increasingly favored in construction projects due to their enhanced strength and durability compared to traditional steel options. The cold drawing process involves pulling steel through dies at room temperature, which improves its mechanical properties. This method produces a finer grain structure, resulting in superior tensile strength and yield strength. Consequently, cold drawn steel bars can withstand greater stresses and strains, making them ideal for demanding construction applications.

In addition to strength, cold drawn steel exhibits exceptional durability. Its manufacturing process reduces the likelihood of defects and inconsistencies, leading to a more reliable material that offers long-lasting performance. These bars are also less prone to deformation under load, which is crucial for maintaining structural integrity over time. By incorporating cold drawn steel bars into construction projects, builders can achieve higher safety standards and reduce the need for frequent repairs, ultimately leading to cost savings and improved project timelines.

Cost-Effectiveness in Long-Term Construction Projects

Cold drawn steel bars have gained significant traction in the construction industry, particularly for long-term projects where cost-effectiveness is paramount. According to a recent report by the World Steel Association, the use of high-quality materials such as cold drawn steel contributes significantly to reducing overall project costs by minimizing maintenance needs and extending the material's lifespan. With a tensile strength that often exceeds regular hot-rolled steel, cold drawn bars offer enhanced durability, leading to fewer replacements and repairs over time.

Moreover, the precision of cold drawn steel bars allows for tighter tolerances and reduced waste during fabrication. A study by the American Institute of Steel Construction highlighted that precise steel materials can decrease fabrication costs by up to 15%. This level of efficiency not only translates to less material being consumed overall but also enhances the overall sustainability of construction projects. As industries strive for greener building practices, choosing cold drawn steel can significantly lower the environmental impact associated with material usage, while simultaneously reinforcing financial prudence in long-term construction planning.

Versatility in Various Construction Designs and Techniques

Cold drawn steel bars are highly valued in construction projects due to their versatility in various designs and techniques. The process of cold drawing enhances the mechanical properties of steel, resulting in stronger, more durable bars that can accommodate a range of structural requirements. This adaptability makes them suitable for use in everything from high-rise buildings to intricate bridge designs, allowing engineers and architects the flexibility to implement innovative solutions tailored to specific project demands.

Moreover, the uniformity and precision achieved through cold drawing contribute to seamless integration in different construction methods. The consistent diameter and smoother finish of these steel bars not only improve aesthetics but also facilitate easier fabrication and assembly. Whether utilized in reinforced concrete structures or in creating complex frameworks, the reliable performance of cold drawn steel bars ensures that they meet the rigorous standards of modern construction. This capability to blend with various materials and techniques underscores their essential role in contemporary architectural engineering, enabling bold designs while maintaining structural integrity.

Top 10 Benefits of Using Cold Drawn Steel Bars in Construction Projects

Related Posts

-

Top 10 Benefits of Cold Drawn Steel Bars You Need to Know

-

Understanding Cold Drawn Steel Bar: Characteristics, Applications, and Benefits

-

2025 Top Cold Drawn Steel Bar Applications and Benefits for Industry

-

Exploring the Unique Properties and Applications of Stainless Steel Wire in Modern Manufacturing

-

What is Carbon Steel and How is it Different from Other Steels

-

Innovative Uses of i Steel Bar in Modern Construction Techniques