2026 Top Rolled Steel Trends Innovations and Applications in Industry

In the ever-evolving landscape of the rolled steel industry, innovative trends are shaping its future. According to a recent report by Research and Markets, the rolled steel market is projected to reach $600 billion by 2026. This growth reflects a rising demand across various sectors, including construction and automotive. However, challenges like environmental regulations and raw material costs remain pressing concerns.

Expert in rolled steel, Dr. John Harrington, notes, "The adaptability of rolled steel technologies is pivotal for a sustainable future." As industries adapt to new technological advancements, the application of rolled steel is becoming more versatile. High-strength rolled steel products are now essential in enhancing structural integrity and improving energy efficiency. Yet, the industry must address some shortcomings in production processes to minimize waste and reduce carbon emissions.

Recent challenges also highlight the need for research and development. Companies must invest in innovation to stay competitive. The balance between meeting market demands and maintaining sustainability is critical. As trends evolve, the rolled steel sector must reflect on its practices to ensure long-term growth and environmental responsibility.

Top Innovations in Rolled Steel Manufacturing Processes for 2026

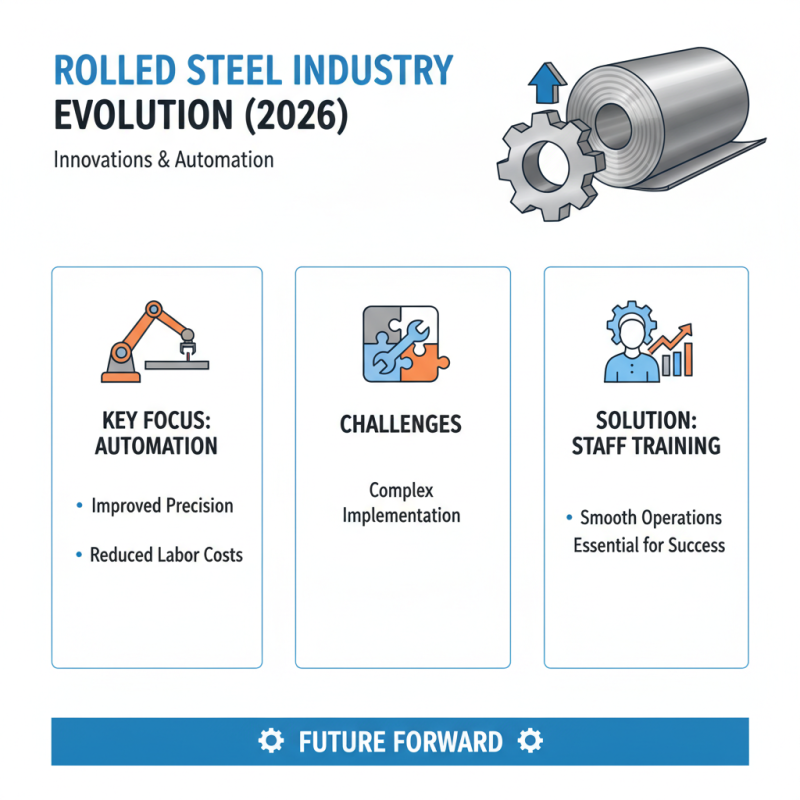

The rolled steel industry is evolving rapidly. Innovations in manufacturing processes are crucial for 2026. One major focus is automation. Automated systems help improve precision and reduce labor costs. However, implementing these systems can be challenging. Staff training is essential to ensure smooth operations.

Another emerging trend is sustainable practices. Manufacturers are seeking ways to reduce waste. Recycled materials are being integrated into production. This not only cuts costs but also benefits the environment. Yet, achieving true sustainability remains a work in progress. Companies must evaluate their entire supply chain.

Additionally, digital technologies are reshaping rolled steel production. Implementing IoT devices can enhance monitoring and control. Smart sensors provide real-time data on temperature and pressure. While these advancements promise efficiency, they also raise concerns about data security. Industry leaders need to address these issues to build trust.

Emerging Trends in Sustainable Rolled Steel Production Methods and Practices

In recent years, the rolled steel industry has been shifting towards sustainable production methods. This change addresses environmental concerns and resource scarcity. Manufacturers are now using less energy and generating lower emissions. Innovative techniques, such as electric arc furnaces, are gaining traction. These methods not only reduce carbon footprints but also enhance efficiency.

A growing trend is the integration of recycled materials to create new steel. This process is less resource-intensive and helps in waste reduction. However, there are challenges. The quality of recycled steel can vary. Ensuring consistent output is crucial for maintaining industry standards. It's not always easy to strike a balance between cost and sustainability.

Tips for adopting sustainable practices include assessing existing processes for improvements. Consider investing in cleaner technologies. Another suggestion is to engage with suppliers focused on eco-friendly materials. Building partnerships can foster innovation. Reflection on current methods is necessary to identify areas for growth. Embracing these changes will lead to a more sustainable future for the rolled steel industry.

Applications of Advanced Rolled Steel in Construction and Infrastructure Projects

Advanced rolled steel is becoming increasingly vital in construction and infrastructure. Its strength and versatility make it ideal for various applications. For instance, steel beams and columns are now common in high-rise buildings and bridges. These structures rely heavily on rolled steel for stability and durability.

In sustainable construction, advanced rolled steel plays a pivotal role. Its recyclability reduces waste and lowers carbon footprints. Many projects now prioritize materials with sustainable properties. This shift presents challenges, as not all rolled steel options meet these criteria consistently. Decisions must reflect a balance between performance and environmental impact.

Infrastructure projects also benefit from innovations in rolled steel. Its applications range from railways to pipelines. The need for efficient transportation systems drives these developments. However, logistical issues often arise. Timely delivery and quality assurance remain areas needing improvement in the industry.

2026 Top Rolled Steel Applications in Construction and Infrastructure Projects

Impact of Automation and Industry 4.0 on Rolled Steel Operations by 2026

The evolution of automation and Industry 4.0 is reshaping rolled steel operations significantly. By 2026, advanced robotics and AI will dominate production lines. These technologies enhance efficiency but also pose new challenges. Many industries still grapple with the integration of automation. This transition isn’t always seamless; it requires substantial investment and training.

Furthermore, data analytics will play a key role in operations. Real-time monitoring can optimize processes and reduce waste. However, reliance on data is a double-edged sword. Cybersecurity threats may increase as companies become more connected. Workers need to adapt to these changes quickly. Skills gaps can hinder progress and affect overall productivity.

The future of rolled steel lies in balancing technology and human expertise. Collaboration between advanced systems and skilled personnel is crucial. Companies must remain adaptable to stay competitive. Challenges will arise, but the potential for innovation is immense. Embracing this change will redefine the industry landscape for years to come.

2026 Top Rolled Steel Trends Innovations and Applications in Industry - Impact of Automation and Industry 4.0 on Rolled Steel Operations by 2026

| Trend/Innovation | Impact on Operations | Projected Adoption Rate (%) | Key Benefits |

|---|---|---|---|

| Automation in Manufacturing | Increased efficiency, reduced labor costs | 80% | Higher output, improved safety |

| IoT Integration | Real-time monitoring of processes | 75% | Enhanced decision-making, predictive maintenance |

| Advanced Data Analytics | Optimized production planning | 70% | Cost reduction, waste minimization |

| Smart Factories | Fully integrated operations | 65% | Seamless workflows, increased customization |

| Sustainable Practices | Reduced environmental impact | 60% | Compliance with regulations, improved brand image |

Market Forecast: Demand for Rolled Steel Products in Key Industrial Sectors

The demand for rolled steel products in key industrial sectors is on the rise. This growth is largely driven by the construction and automotive industries. Both sectors rely heavily on rolled steel for structural components and automotive parts. The need for stronger, lighter materials to improve efficiency is pressing.

Innovation plays a crucial role in this shift. Advanced production techniques are enhancing the quality and performance of rolled steel. Manufacturers are exploring new alloy compositions to meet specific needs. There’s a challenge though: adapting to ever-changing market demands takes time and resources.

Sustainability is another concern. Many sectors are pushing for greener solutions. The rolled steel industry must find ways to reduce its carbon footprint. This transition isn’t easy, and mistakes can happen. The road ahead will require constant reevaluation and adaptation. Industrial players will need to collaborate while staying competitive.

Related Posts

-

The Advantages of Using Rolled Steel in Modern Construction and Design

-

The Ultimate Guide to Rolled Steel: Innovations, Applications, and Sustainability in 2023

-

Understanding the Essential Role of Steel in Modern Construction and Infrastructure

-

Top 10 Reasons You Need Steel for Your Construction Projects

-

How to Select the Right Bar Steel for Your Construction Projects

-

The Best Types of Steel Bars for Construction and Their Benefits