2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations

The stainless steel wire industry is poised for transformative changes as we approach 2025, driven by both technological innovations and evolving industrial needs. According to a recent report by Grand View Research, the global stainless steel wire market is expected to reach USD 10.84 billion by 2025, growing at a CAGR of 6.8% due to the increasing demand for durable materials in various applications, ranging from construction to automotive manufacturing. As industries prioritize sustainability and performance, the focus on advanced stainless steel wire solutions has never been more critical.

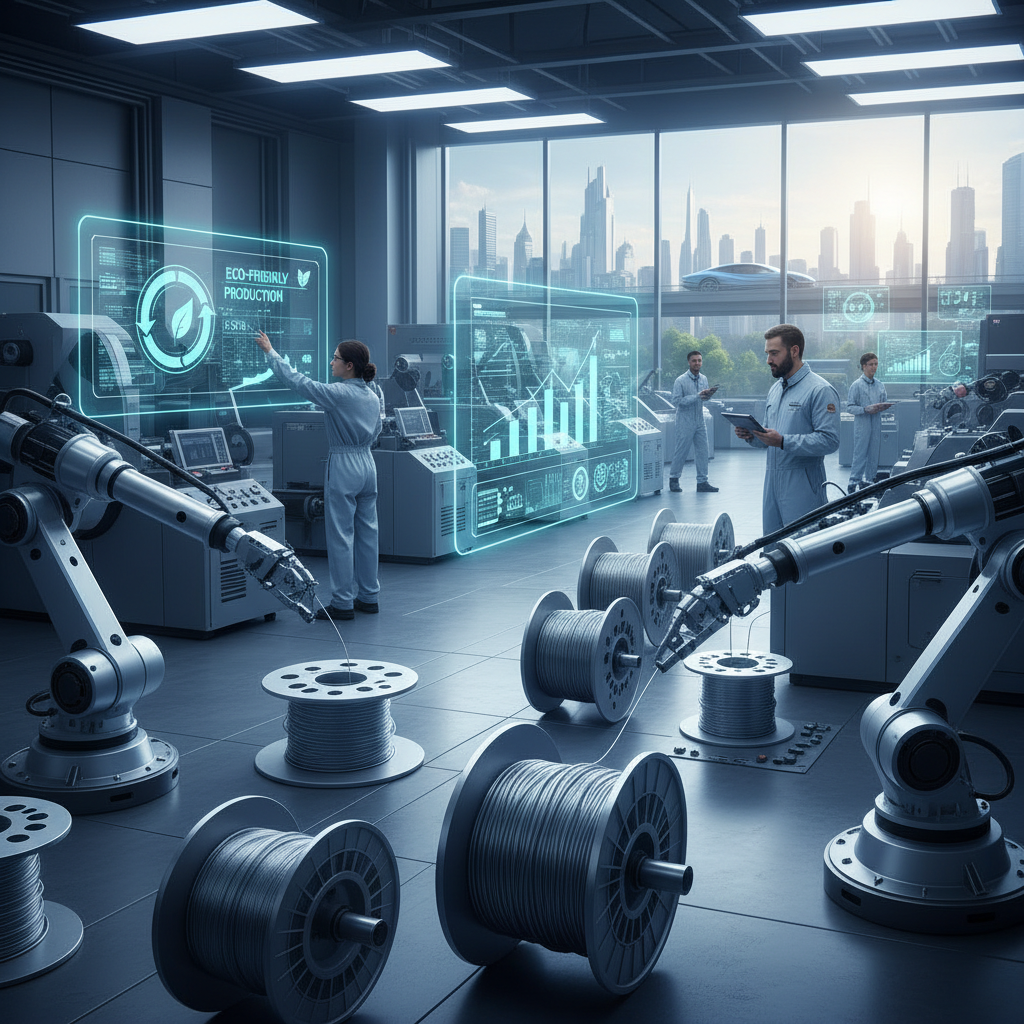

Expert insights also highlight the significance of these trends. Dr. Emily Chen, a leading material scientist at the Steel Wire Association, emphasizes, "The future of stainless steel wire is closely tied to developments in automation and eco-friendly production methods, enabling industries to meet both quality and sustainability standards." As we explore the top trends in stainless steel wire for industrial applications, it becomes evident that innovation and efficiency will play pivotal roles in shaping the industry landscape over the next few years. This article aims to dissect these trends and offer a comprehensive guide on how businesses can adapt and thrive in a rapidly changing environment.

Emerging Applications of Stainless Steel Wire in Robotics and Automation

The integration of stainless steel wire in robotics and automation is witnessing significant advancements, particularly in enhancing manufacturing capabilities. Emerging applications highlight the use of stainless steel wire in the construction of robotic arms and CNC machines, allowing these systems to perform a broader range of industrial tasks with greater efficiency. The seamless integration of materials like stainless steel in robotic systems not only improves their durability but also enhances their operational precision, making them ideal for challenging environments.

As automation continues to evolve, the durability and strength of stainless steel wire become crucial for applications in heavy-duty settings. Innovations in welding technologies, such as those facilitating wire-laser deposition methods, open new avenues for exploiting the unique properties of stainless steel. This evolution is paving the way for more sophisticated manufacturing processes in industries like defense, where high-performance materials are essential. The push towards these advanced applications underscores the pivotal role of stainless steel wire in the future landscape of robotics and automation.

2025 Top Trends in Stainless Steel Wire for Industrial Applications and Innovations

| Trend | Description | Emerging Applications | Innovation Type |

|---|---|---|---|

| Lightweight Alloys | Development of lighter stainless steel wire for reduced load. | Robotic arms and automated transport systems. | Material Innovation |

| Corrosion Resistance | Advancements in corrosion-resistant coatings for wire. | Outdoor robotics in harsh environments. | Coating Technology |

| High Tensile Strength | Enhancements to strength-to-weight ratios of wires. | Aerospace robotics and high-stress applications. | Mechanical Innovation |

| Smart Materials | Development of wires that can change properties based on stimuli. | Adaptive robotics and auto-adjusting machinery. | Sensor Technology |

| Eco-friendly Production | Sustainable methods for producing stainless steel wire. | Green automation solutions. | Sustainable Practices |

Advancements in Corrosion Resistance Technologies for Industrial Wire

The advancements in corrosion resistance technologies are set to redefine the landscape of stainless steel wire applications in industrial settings. With the increasing demand for durable materials that can withstand harsh environments, innovations in coatings and alloy compositions have emerged as critical factors in enhancing the longevity and performance of stainless steel wire. For instance, advancements in electrodeposition techniques have allowed for the application of robust protective layers that significantly improve resistance to corrosive agents. This not only extends the lifespan of the wire but also reduces the need for frequent replacements, ultimately contributing to cost savings for industries.

Moreover, the development of new alloy formulations that incorporate elements such as molybdenum and nickel has shown great promise in improving overall corrosion resistance. These high-performance alloys are designed to perform under extreme conditions, such as exposure to saltwater or acidic environments, making them ideal for industries like marine, construction, and chemical processing. As manufacturers continue to innovate and adapt, we can expect to see a wider range of applications for stainless steel wire, tailored specifically to meet the rigorous demands of various industries while ensuring sustainability and efficiency.

Sustainability Trends in Stainless Steel Wire Production and Recycling

Sustainability is becoming increasingly important in the production and recycling of stainless steel wire, reflecting a broader trend in industrial applications. As the global stainless steel market is projected to grow from USD 134.3 billion in 2025 to USD 173.6 billion by 2035, achieving a CAGR of 2.6%, there is a significant shift towards eco-friendly practices. Innovations in recycling processes are crucial, with advanced technologies being adopted to enhance the efficiency of stainless steel wire recovery. This not only reduces waste but also conserves valuable resources, aligning with the principles of a circular economy.

In India, the steel wire sector is experiencing rapid expansion as manufacturers invest in sophisticated technologies to improve production scale and specialization. The focus on sustainability is evident as companies aim to reduce their carbon footprint. Reports indicate that the market for stainless steel sheet, a vital component in various applications, is expected to showcase a CAGR of over 6.1% from 2025 to 2032, emphasizing the growing demand for sustainable materials. The push for sustainable practices in stainless steel wire production and recycling signifies a transformative phase in the industry, setting the foundation for future innovations.

Innovative Coating Solutions Enhancing Performance of Stainless Steel Wire

Innovative coating solutions are rapidly transforming the landscape of stainless steel wire applications in various industrial sectors. These advanced coatings not only enhance the performance of the wire but also extend its lifespan and increase its resistance to environmental factors such as corrosion, temperature fluctuations, and mechanical wear. By employing techniques such as electroplating, powder coating, and polymer-based coatings, manufacturers are able to create surfaces that improve the overall durability and functionality of stainless steel wires used in demanding applications like automotive, aerospace, and construction.

Moreover, these innovative coatings can tailor the properties of stainless steel wire to meet specific industrial needs. For example, certain coatings can provide enhanced electrical conductivity or reduce friction, making the wires more efficient for applications like electrical connectors and springs. Additionally, innovations in nanotechnology are introducing self-healing coatings that have the ability to repair minor damage autonomously, further boosting the reliability of stainless steel wires in critical applications. As the demand for high-performance materials continues to grow, the development of these innovative coating solutions will play a pivotal role in shaping the future of stainless steel wire in industrial contexts.

Market Insights: Demand Growth and Future Prospects for Stainless Steel Wire

The demand for stainless steel wire is anticipated to experience significant growth in various industrial applications over the next few years. As industries increasingly shift towards durable and corrosion-resistant materials, the use of stainless steel wire is becoming essential in sectors such as construction, automotive, and aerospace.

Factors driving this demand include the rise of renewable energy technologies, where stainless steel wire is utilized in wind turbines and solar panel installations. Enhanced performance characteristics and longevity make stainless steel wire a preferred choice for manufacturers looking to optimize their products.

Factors driving this demand include the rise of renewable energy technologies, where stainless steel wire is utilized in wind turbines and solar panel installations. Enhanced performance characteristics and longevity make stainless steel wire a preferred choice for manufacturers looking to optimize their products.

Future prospects for the stainless steel wire market show promising trends in innovation and technological advancements. The integration of smart manufacturing processes, including automation and additive manufacturing, is expected to streamline production and enhance product quality. Additionally, the development of specialized stainless steel alloys tailored for specific applications may open up new market opportunities. As industries continue to evolve and seek high-performance materials, the stainless steel wire market is poised for a robust expansion, reflecting both its adaptability and the increasing emphasis on sustainable and efficient industrial practices.

Related Posts

-

Exploring the Unique Properties and Applications of Stainless Steel Wire in Modern Manufacturing

-

10 Essential Tips for Choosing the Right Stainless Steel Wire Rod

-

The Future of Hot Rolled Bars in Construction and Manufacturing Industries

-

Top 10 Benefits of Cold Drawn Steel Bars You Need to Know

-

Understanding Cold Drawn Steel Bar: Characteristics, Applications, and Benefits

-

Exploring the Versatile Applications of Steel Wire Rod in Modern Construction and Manufacturing